|

|

|

|

|

| Lear |

|

| Max Ramp Weight

35-345 & Sub with ECR 2234 36-002 to 045 with AAK 80-2 36-046 & Sub |

|

| Max Ramp Weight

36-002 to 045 without AAK 80-2 |

|

| Max Takeoff Weight

35-067 to 344 with AAK 80-2 35-345 & Sub with ECR 2234 36-002 to 017 with AAK 76-4 and AAK 80-2 36-046 & Sub |

|

| Max Takeoff Weight

35-067 & Sub with AAK 77-8 35-001 to 344 with ECR 1495 36-002 to 045 without AAK 80-2 |

|

| Max Landing Weight

35-356 & Sub 36-002 to 046 with AAK 80-3 36-047 & Sub |

|

| Max Landing Weight

36-002 to 046 with AAK 80-3 |

|

| Max Wing Bending Weight ( no restrictions )

Xfer prior to Total wing fuel = 2250 lbs If Xfer fails, Vmo = 325 kts |

---- 14,000 lbs |

| Max Baggage Comp. |

|

| Typical Empty Weight |

|

* All weight in excess of the Max ZFW must be fuel in the Wing and tip tanks.

The above weights are maximum certificated limits. The actual maximum weights for a particular flight may vary a great deal due to performance limitations. If the aircraft can not meet the required "Takeoff Field Length" and "Climb" limitations, (engine out climb performance), the maximum takeoff and/or landing weights are reduced such that the requirements are met. See the performance charts in the AFM for details.

Speeds

|

|

|

| Vmo

|

359 kts |

| Mmo

|

0.74 M 0.74 M |

| Va |

|

| Vfe 8 Deg

20 Deg 40 Deg |

183 kts 153 kts |

| Vlo

Vle |

260 kts |

| Vsb

(Not with flaps when airborne) |

|

| Vmca

Vmcg |

103 kts |

| Nosewheel Steering

Primary Wheel Master |

Authority 45 kts |

| Max Tire Groundspeed |

|

Yaw Damper Off for T.O., On for Flight, Optional for LDG

Airplane shall be configured for landing by 500 ft AGL

Lear Jet

|

|

|

| Max Alt T.O. & LDG |

|

| Max Enroute Altitude |

|

| Max Cabin Pressure

Relief |

10.0 psi |

| Min Temp T.O. & LDG

Max Runway Clutter |

|

| Max Tailwind T.O/ LDG

Max X-Wind Takeoff / Land |

24.7 kts |

| Max Runway Slope |

|

| Max Fuel Imbalance |

|

| Max Tip Fuel / Landing |

|

| Load Factor Limit

Flaps Up Flaps Extended |

2.00 G |

Engine Limitations

Note: Idle for 3 Minutes prior to takeoff if ambient temp is below

- 25 C

See AFM for Approved oils. Do not mix brands of oil.

Engine Limitations

Lear 35 / 36

|

|

N1 | N2 |

|

|

|

|

|

|

870 C |

10 Sec |

|

|

|

|

870 C |

5 Seconds |

|

|

|

|

|

|

|

|

|

|

|

|

|

Max Transient |

105.0 % |

105.0 % |

---- |

5 Seconds |

|

|

|

| Max Oil Temp

Max Cont. Min Normal |

127 C 30 C |

| Min Oil Temp for Start |

|

| Max oil consumption / 25 hours |

|

| Max Oil Press |

|

| Min Oil Press |

|

| Normal Oil Press |

|

Systems

|

|

Primary Flight Controls

The ailerons, elevator and rudder on the Lear Jet

are manually actuated by the pilots. Aileron and rudder trim is achieved

with trim tabs on the rudder, and left aileron. These trim tabs are

positioned by electric motors located inside the left aileron and the rudder

it's self. Pitch trim is achieved by changing the position of the

moveable horizontal stabilizer. There are two trim motors that will

do this, a primary, and a secondary. The aileron, rudder,

and primary pitch trim are controlled with a thumb switch on the left side

of the Capt.'s and right side of the Co-Pilot's control yoke. The

secondary trim is actuated by the autopilot, and can be controlled by an

electric switch on the console in the event the primary trim fails.

The aircraft does have an autopilot, although not

a very good one until you get to the 31, 45, 55 or 60. The ailerons

and elevator may be moved by the autopilot servos, and the rudder is equipped

with a primary and secondary yaw damper. Both yaw dampers are required

for flight although only one may be engaged at a time.

The Lear Jet has two stall warning systems.

They are the same. Both are required for flight. Angle of attack

information is given to the system by two angle of attack vanes located

on the left and right sides of the nose of the aircraft. These vanes

are heated when the pitot heat switch is on. They get hot enough

to burn you, so touch them with caution.

About 7% above a stall, the system warns you with

a flashing stall warning annunciator light, and by activating the stick

shaker. At about 5% above a stall, the autopilot pitch servo applies

an 80 pound push on the elevator. If you do not notice this, you

deserve to crash! It is hard to ignore.

There is a "Wheel Master" button just below the

trim actuator on each pilot's yoke. It is a handy little guy.

It interrupts any elevator trim action, deactivates the stick pusher, disengages

the autopilot, and will engage the nosewheel steering if the gear is down.

The trim check very important on the Lear Jet, as the trim system on this aircraft, if not properly set can KILL you within seconds after liftoff. Excuse the lack of tact here, but it's a fact. Perform the trim check prior to takeoff.

Flaps

The flaps on the Lear are hydraulically actuated.

The flaps are controlled in one of two ways, depending on the model lear.

Most have one switch with three positions, Extend, retract, and off.

Select extend, or retract until the flaps are in the desired position,

then select off. Some Lears have preselect where you place a lever

in the desired flap position, and the flaps extend to the position requested.

If the flaps will not extend, add 30 kts to your approach speed and 30%

to your landing distance.

There is pressure relief valve in the flap system

that will prevent damage to the flaps if they are inadvertently extended

or left down at speeds in excess of their operating limitations.

Spoilers

Lear Jets are equipped with spoilers. They

may be deployed up to Vmo / Mmo in flight only when the flaps are retracted.

On landing, they should be deployed just after touchdown. They are

hydraulically actuated, and electrically controlled. They have two

positions, fully deployed, and stowed.

Spoilerons

The Lear 30 and later models are equipped with spoilerons.

They may be deployed up to Vmo / Mmo in flight only when the flaps are

retracted. On landing, they should be deployed just after touchdown.

They are hydraulically actuated, and electrically controlled. They

have two positions, fully deployed, and stowed.

When the flaps are more than 25 deg extended, the

spoilers will extend on one side or the other to provide better roll control

at approach and landing speeds. The spoiler on the same side as whatever

aileron is deflected upward will match the position of that aileron.

This kills some of the lift on that side, and makes low speed roll control

much more effective than on the 20 series airplanes. This feature

requires AC power to function.

Nosewheel Steering

The nosewheel steering on the Lear is electric.

It requires both AC and DC to operate. Steering is engaged with the

wheel master switch, or by a "Steer Lock" switch on the left side of the

Capt.'s panel on 20 series airplanes, and the center pedestal on 30 series

and later models. Maximum speeds for use of nosewheel steering is

either 45 knots, or 10 knots, depending on the steering mode selected,

and / or loss of wheel speed input from more than one of the right three

main wheels. See AFM for details.

Landing Gear

Like all other aircraft intended for more than one

flight, the Lear jet has a landing gear. It is extended and retracted

hydraulically, and controlled electrically. It can be extended with

high pressure nitrogen if the normal extension fails.

Brakes

Each main landing gear on the Lear Jet has

two wheels and tires. Each wheel has it's own hydraulic brake, with

anti-skid protection. The brakes on the left gear are controlled

by pressure applied to either of the left brake pedals, and the right brakes

work the same way from the right pedal pressure. The anti-skid system

can relieve the brake pressure on any individual wheel.

If the hydraulic brake system fails, there is an

alternate brake system that will apply the brakes with high pressure nitrogen.

The same bottle is used for emergency gear extension. The emergency

brake system does not provide any anti-skid, or differential braking capability.

It is a good system, and if you use it with your brain engaged, it works

fine.

** Prior to takeoff, ALWAYS check the 3 Killer Items **

|

|

|

|

Fuel Capacity

|

|

|

|

|

|

|

|

|

0.77 Mach / 440 kts |

|

|

| Fuel Type |

|

|

| Jet A / Jp-5 |

|

|

| Kerosene |

|

|

| Jet B / Jp-4 |

|

|

| Avgas |

|

15,000 ft & 25 hr max |

Note:

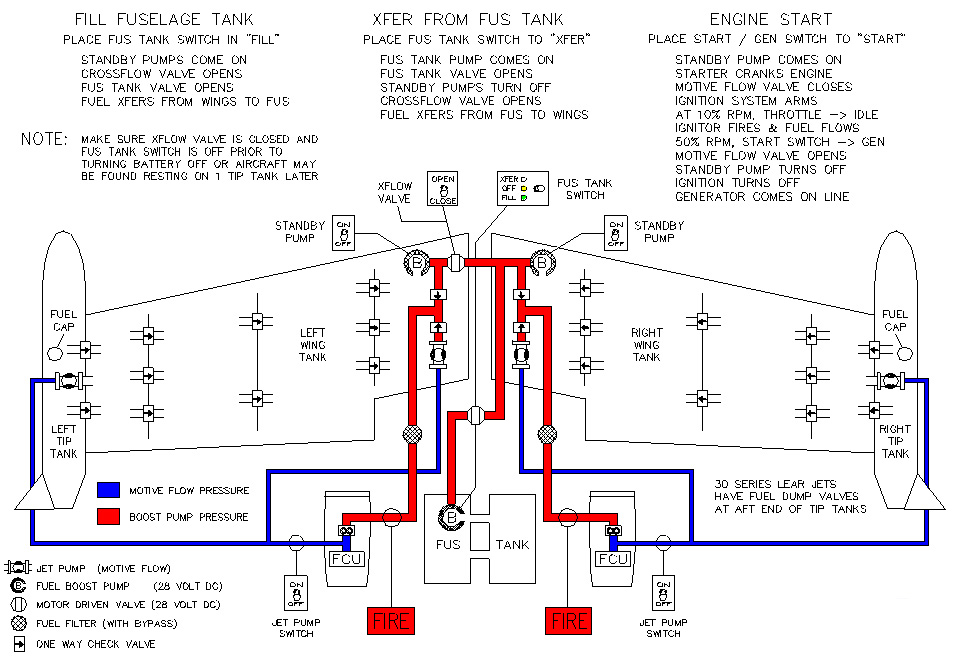

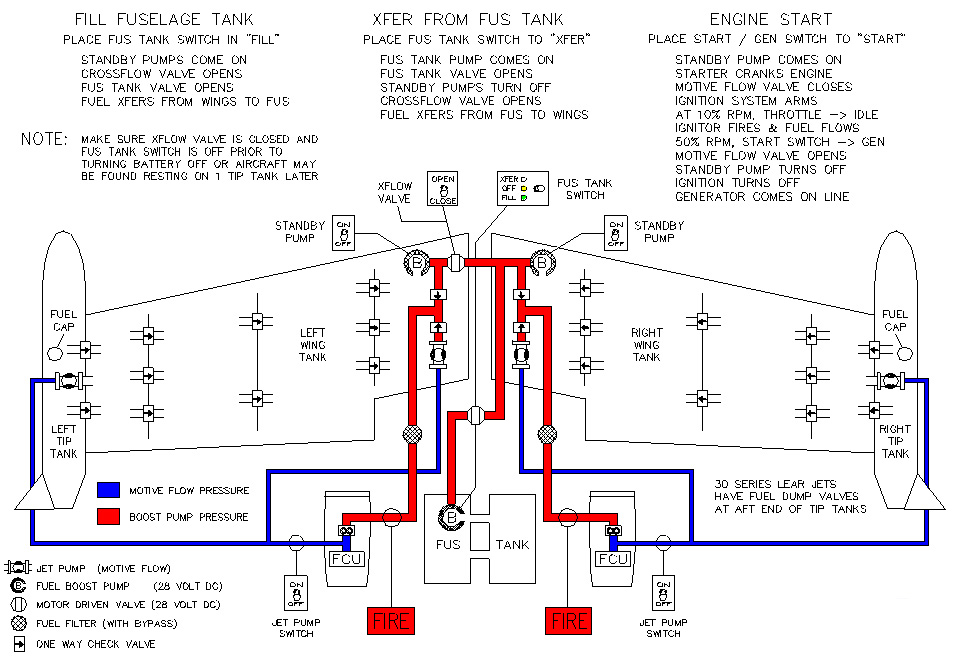

This section describes the basic fuel system on

Lear Jets. The 28 and 31 models have no tip tanks, but are otherwise

about the same, and the 23 has a different crossflow arrangement, and fills

the fuselage from the left wing tank only. The 36 models have a means

to fuel the fuselage tank with a fuel hose, and to gravity transfer all

but about 400 lbs of the fuselage fuel without the fuselage pump.

Otherwise all 20 thru 50 series Lear have basically the same fuel system.

|

|

|

|

|

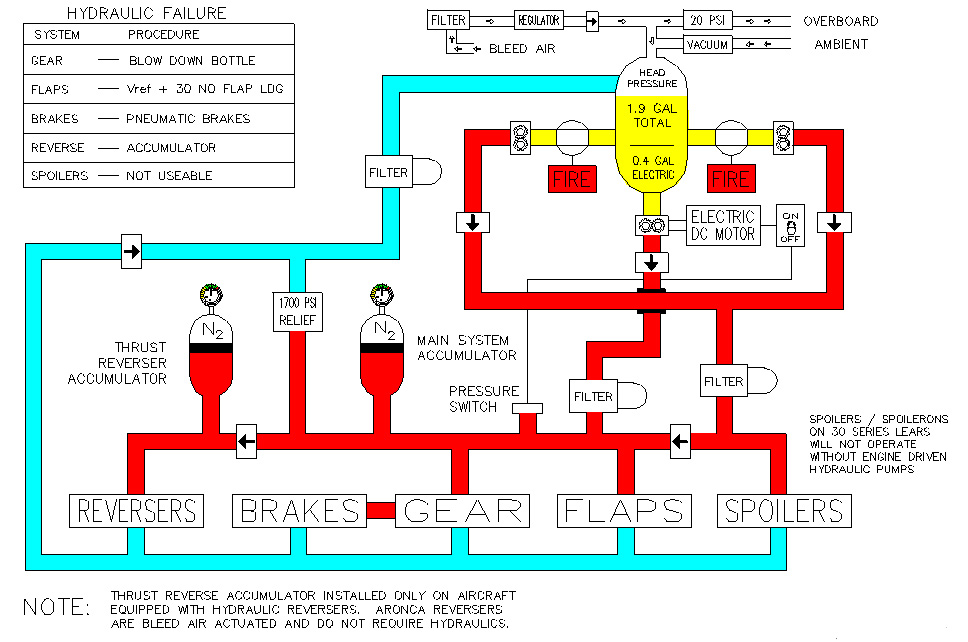

The Lear Jet hydraulic system consist of 2

engine driven, and one electric hydraulic pump, a 1.9 gallon reservoir,

an accumulator (two accumulators if Dee Howard reversers are installed)

and a couple of pressure relief valves. The fluid is 5606 therefore

if you spill some on yourself, you won't wind up looking like you and Michael

Jackson share the same dermatologist. The system operates the landing

gear, normal braking with anti-skid, the flaps, spoilers, and thrust reversers

(except aeronca) if the aircraft is so equipped.

The reservoir is pressurized by bleed air on later

models, and cabin air on earlier Lears. This is to prevent foaming.

The engine driven hydraulic pumps can only access 1.5 of the 1.9 gallons

of hydraulic fluid. The additional 0.4 gallons can be used by the

electric hydraulic pump only. It can extend the landing gear, the

flaps, provide normal braking with anti-skid, and on the 20 seriesonly,

extend the spoilers. The hydraulic thrust reversers have their own

accumulator, and should be useable even with total hydraulic failure.

The system has two pressure relief valves, one main

system relief valve, that relieves at 1700 to 1750 psi, and one relief

valve in the flap system that relieves about 1650 psi. See "Flaps'

in the flight controls section for more details on this.

With total hydraulic system failure, blow the gear

down, approach at Vref + 30 kts, use pneumatic brakes, and plan on 1.7

to 2.0 times your normal landing distance. T/R's may work!

|

|

|

|

|

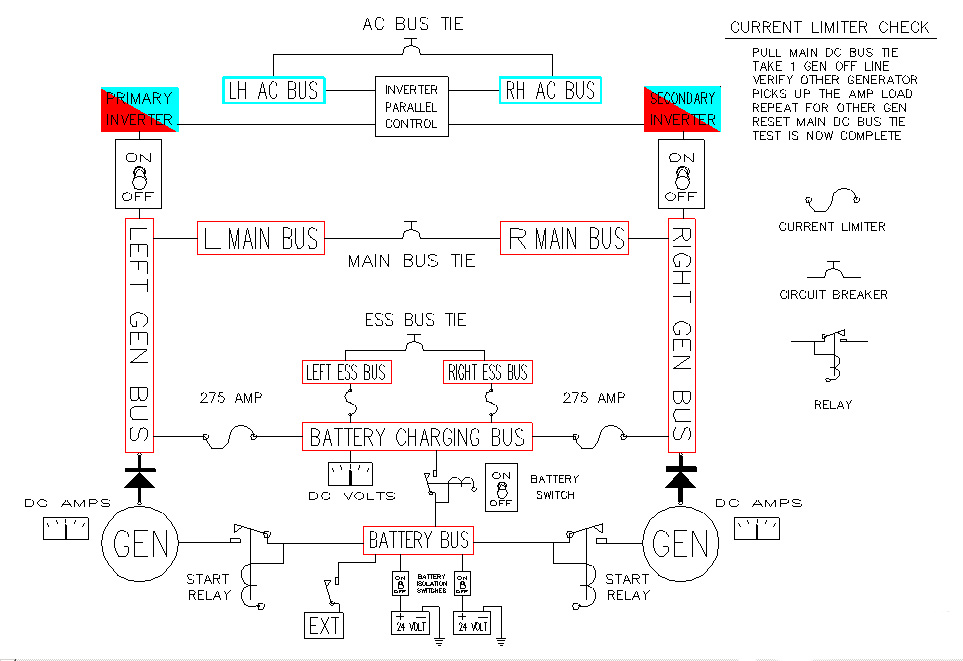

"DC" Electrical

The Lear Jet 30 series DC electrical system is only slightly more complex than the earlier models. It consists of: Two batteries, usually one, but sometimes two standby batteries, two starters, two generators, several busses, some relays, current limiters, quite a few circuit breakers, and two battery switches. The main difference between the 30 series (and some later 25's) is the added "Essential" busses. They are busses that can still receive battery power with both current limiters blown.

The current limiters connect the generators to the battery

bus. The starting current goes through the start relay, and does

not pass through the current limiter. The current that recharges

the batteries does. If you blow a current limiter other than due

do an electrical short, it will probably be just after engine start when

you put the first generator online. Because the batteries are in

a discharged state, they want all of the electrons they can eat.

This is sometimes more than the current limiters can take.

|

|

|

|

|

|

| Generators

Flight |

400 Amps |

| Batteries 1 & 2

Battery 3 |

24 Volt / 04 Amp Hour |

Standby Battery

The standby battery switch has three positions: OFF, STANDBY, and ON. In the ON position the emergency battery powers the small third attitude indicator, it's light, and the control circuits for the landing gear and flap systems. The three green landing gear lights are also powered by the emergency battery, and will illuminate when the gear is down and locked. The red "gear door not locked" lights are not powered by this battery. In standby, it powers just the gyro and it's light. Most of these batteries will charge in the ON and Standby positions, however, some, such as the ones in the Lear 28 must be left "ON" to be charged. Some later model aircraft may be equipped with a second standby battery. This will usually power an emergency comm radio, and whatever other devices the customer would like.

If you experience loss of all main DC bus power for any reason, remember the following:

1. Emergency battery switch to ON. Landing gear extension

will be normal

except for the loss of the red gear

door warning lights.

2. Landing gear warning horn will be inop.

3. Engine stator and nacelle lip heat are on.

4. Wing and tail anti-ice, pitot static, and angle of attack

probe heat will be inop.

5. Windshield Heat will fail in the last position selected.

6. Tank to tank fuel transfer will not be possible if crossflow

valve

was closed at time of power loss.

If crossflow valve was open, the

boost pumps will fail, making

pressure fuel transfer impossible, however,

the crossflow valve will remain

open, allowing some fuel transfer due to a

very reliable power source called

gravity.

7. The AC electrical system will be inop as it receives

it's power from the DC system.

8. The hydraulic system will be inop, except for the landing

gear and flaps, as their

control circuitry is powered by

the emergency battery when the "ON" position

is selected.

9. Nosewheel steering will be inop, as it requires

both AC and DC electrical power.

10. Anti-Skid system is inop.

These things may require some thought as to how one wishes to conduct the remainder of a flight.

Normal Operation:

Battery switches ON, before engine start,

all DC busses are powered by batteries or GPU. After engine start,

all busses are powered by the generator(s), and the batteries are recharged.

Battery Overheat

Respective battery switch OFF. This prevents

battery charging. DC busses powered by generator(s). Monitor

temp of offending battery. If your lear does not have dual battery

switches, use the battery disconnect switch for the offending battery.

All 30 series and later Lears have dual battery switches.

"AC" Electrical System

A Lear Jet is usually equipped with two inverters.

A third inverter is an option on Lear 24's and all later Lear Jets.

Almost all of the Lear 30 series are equipped with two solid state inverters.

Either one can supply AC power to all items on the aircraft that require

it. They normally operate in parallel, but if one fails, the other

picks up the remaining load automatically. An AC paralleling unit

aligns the phase of the two inverters to make them work in parallel.

The AC items on the Lear include: Gyros, Autopilot,

Altitude Alert, Mach trim system, Nosewheel Steering, Engine pressure gauges,

and a few other items that vary from aircraft to aircraft.

|

|

Lear Jets of the 30 series and later are all certified

for flight into known or forecast icing conditions. Starting from

the front of the airplane, the radome is anti-iced by alcohol that is pumped

onto it through a plastic nozzle located at the very front of the airplane.

The same alcohol pump provides emergency anti-ice for the left windshield.

You have about 90 minutes for the radome, and 45 minutes for the radome

and windshield together.

The pitot tubes, static ports, and angle of attack

vanes are electrically heated, controlled by the "Pitot Heat" switches

in the cockpit. The windshields are heated with engine bleed air.

The wing and horizontal stab leading edges are heated by bleed air.

Engine nacelles and stators are heated by bleed

air. The bullet shaped nose cone for the 731 engine was heated with

bleed air as well, however almost all of the airplanes have been fitted

with the conical spinners, and require no heat, as their shape and rotation

does not allow large enough amounts of ice to form to pose any hazard to

the engine.

|

|

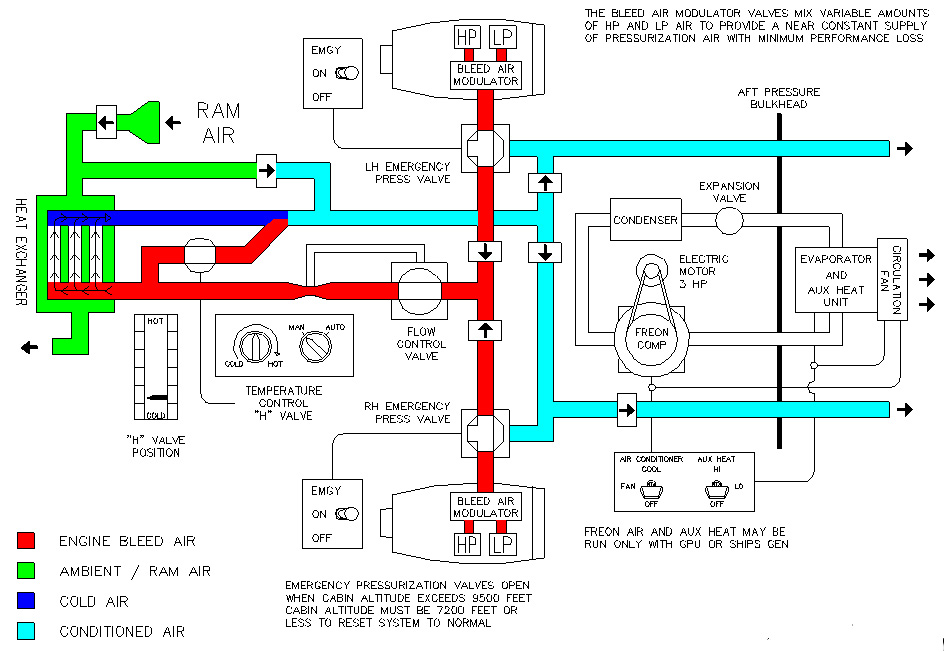

The Lear 35 / 36 is pressurized, like most airplanes,

by engine bleed air. This air comes from the HP and LP bleed sources

on the engine through a "BSV" (bleed switching valve) that regulates the

bleed air pressure by controlling the mix of LP and HP air. This

air goes through a heat exchanger in the tailcone of the airplane, and

is cooled, then goes into the cabin. Temperature is regulated by

a "Damper Valve". This valve controlls the ambient airflow across

the non pressurized side of the heat exchanger. This does not

provide enough cooling for low altitude and hot weather, so a freon airconditioner

is provided for use below 18,000 feet.

Emergency pressurization air is provided by way

of the windshield heat system. Place the defog knob so the windshield

air goes to the inside of the airplane, and you have another source of

air for pressurization. The newer models have two emergency bleed

valves that will automatically open when the cabin altitude exceeds about

9,500 feet. These valves allow uncooled bleed air to pressurize the

cabin.

On the outflow side of things, the cabin pressure

is regulated by a main outflow valve, located at the forward end of the

pressure vessel. The automatic pressurization system requires AC

power. In the event the automatic pressurization fails, cabin pressure

may be controlled pneumatically, by the "Cherry Picker" that uses air to

move the outflow valve. Maximum differential relief between

9.3 and 10 psi, and negative pressure relief at - 0.25 psi, and positive

pressure depending on the model and serial number airplane. This

"Safety outflow valve" is strictly mechanical. It requires no electrical

power.

|

|

|

|

|

Here are some basic flight profiles that I have used over the years. They are not the only way to fly the airplane, but have worked for me since I started giving training and checkrides in the Lear a little over 20 years ago. In the event of a difference between this and the Aircraft Flight Manual, the flight manual is the document to follow.

Steep Turns

1. Enter at 250 KTS indicated AIRSPEED.

2. Bank aircraft 45 deg. As passing 30 deg bank,

pitch up 2 deg. Add power to maintain speed.

3. Lead roll out by 15 deg. Passing 30 deg bank, pitch

down 2 deg to maintain altitude.

4. Maintain 250 KTS and assigned heading.

Stall - Cruise Configuration

1. Compute Vref & set AIRSPEED bugs.

2. Maintain assigned altitude and set power to 50%

N1.

3. Trim for level flight until passing 150 KTS.

Maintain altitude with necessary back pressure.

4. At stick shaker or stall warning lights,

throttles to " MAX POWER "

5. Call " MAX POWER Flaps Approach.

6 Reduce pitch ONLY to the extent necessary

to eliminate symptoms of the stall.

7. Reestablish assigned altitude.

8. At Vref + 30 KTS, call " Flaps Up, After Takeoff

Checklist. "

9. Maintain AIRSPEED and altitude as directed.

Stall - Takeoff Configuration

1. Compute Vref, set AIRSPEED bugs & select flaps 20.

2. Maintain assigned altitude and set power to 50% N1.

3. Trim for level flight until passing 150 KTS.

4. Maintain altitude with necessary back pressure.

5. At stick shaker or stall lights, advance throttles & call

" MAX POWER ".

6. Reduce pitch ONLY to the extent necessary to eliminate symptoms

of the stall.

7. Reestablish assigned altitude.

8. At Vref + 30 KTS, call " Flaps Up, After Takeoff Checklist.

"

9. Maintain AIRSPEED and altitude as directed.

Stall - Landing Configuration

1. Slow to flap speed, set 60% N1 & Set bug to Vref.

2. Maintain assigned heading & altitude.

3. Below 198 KTS, " Flaps 8 deg".

4. Below 183 KTS, " Flaps 20 deg ".

4. Gear Down, perform Landing Check

5. Below 150 KTS, " Full flaps. " trim to Vref. Establish

a 400-700 feet/min sink rate at Vref.

6. Level off at designated altitude W I T H O U

T increase in power

7. Maintain altitude until first indication of a

stall. (Shaker or stall lights)

8. Apply MAX power lower nose only as much as required

to eliminate the stall warning.

At Vref minus 10 KTS

M I N I M U M speed, call for " Flaps 20 deg", and increase the

pitch attitude to 10 deg nose

up at about 1 deg / sec.

9. When VSI & Altimeter indicate positive rate of

climb call " Positive rate, Gear Up ".

10. Establish 7.5 deg nose up attitude.

11. At Vref + 30 KTS, Call " Flaps Up, After Takeoff Checklist

".

12. Return to entry heading and altitude or as directed.

ILS Approach - Two Engines

1. Intercept LOC at 140-160 KTS and Flaps 20 deg.

2. One dot prior to intercepting Glide Slope, call " Gear Down

Landing Check ".

3. When ON the glidepath, call " Full Flaps ".

4. Establish Vref to Vref + 5 KTS & track LOC & GS until

Minimums.

ILS Approach - One Engine

1. Intercept LOC at 140-160 KTS and Flaps 8 deg.

2. One dot prior to intercepting Glide Slope, call " Gear

Down Landing Check ".

3. When ON the glidepath, call "Flaps 20 deg".

4. Establish Vref + 20 KTS & track LOC & GS

5. At 100-150 Ft AGL, Full flaps, power idle & land.

Non Precision Approach - One or Two Engines

1. Intercept Final Approach Course at 140 KTS and

Flaps 20 deg.

2. Crossing Final Approach Fix, call " Gear Down

Landing Check ".

3. Descend to and maintain MDA until Field in Sight

or MAP is initiated. ( As Appropriate ).

4. If Landing is to be made, call " Full Flaps "

when intercepting a glidepath appropriate for a

normal landing. For one

engine INOP, Vref + 20 KTS until 100 feet AGL, then " Full

Flaps" so as to descend thru 50

ft AGL at Vref as in a normal landing.

No Flap Approach

1. Vref + 40 KTS until established on Final Approach.

2. Vref + 30 KTS on final.

3. Approach angle NORMAL. A flat approach will usually

result in a longer landing roll.

Go Around or Missed Approach

1. "Max Power", Rotate to 10 deg, " Flaps 20 deg".

2. Positive Rate of Climb, " Gear Up ", Vref + 30, " Flaps up,

After Takeoff Checklist ".

3. Climb at 200 KTS.

4. Engine Failure or Fire Checklist if Appropriate.

Takeoff

1. Set V2 on Capt. Airspeed & V1 on Co-Pilots Airspeed.

2. At V 1, BOTH hands on Yoke.

3. Vr, Rotate to 15 deg ( 2 eng ) 12 deg ( 1 eng ).

4. Climb at 15 deg pitch, ( 2 eng ) or V 2 ( 1 eng ).

5. At 400 ft & V2+30 KTS, "Flaps Up After T.O. Check ".

6. Engine Failure or Fire Checklist if Appropriate.

7. Climb 200 KTS to 3000 AGL then 250 Kts.

Rejected Takeoff

1. Proceed as in normal takeoff until malfunction dictates that

the takeoff be rejected.

2. Capt. calls "Abort" (Co-Pilot may call Abort if Capt elects

to delegate that authority).

3. Thrust levers to idle

4. Spoilers extend.

5. Wheel brakes as necessary.

6. Thrust Reverse OR Dragchute deploy. (Never Both at the

same time!!)

7. If another takeoff is contemplated consider brake energy &

appropriate turnaround time.

Emergency Descent

1. Oxygen masks on within 5 sec of cabin pressure

loss.

2. Check passenger oxygen masks deployed.

3. Select Oxygen mask microphone.

4. Ignition ON.

5. Thrust levers to idle.

6. Spoilers and Landing Gear, Extend.

7. Auto Pilot OFF.

8. Initiate 45 deg bank if desired.

9. Vmo/Mmo minus 10 kts to 14,000 or MEA as

required.

10. Clean up & proceed to nearest suitable airport if appropriate.

Condition of aircraft or

reduced range due to low

altitude may make flight to original destination unwise.

Back to: Airplane Driver's Network