|

|

|

|

|

G III / SN # 300 thru 356, # 358 thru 401 and # 875

This guide addresses only the G III DC model.

The G III with the AC electrical system is much more like a G IV from an

electrical standpoint. Other than electrical, the G III's are

pretty much the same. Of all the corporate aircraft I have flown,

( 22 Type Ratings ) the G II-B and G III are are my favorites.

The G III is about two and a half feet longer than the G II-B. This

amounts to about two million dollars per foot. The G III is quieter

in the cockpit due to the improvements to the windshield design over the

G II's The Falcon 2000 is hard to beat, but the Gulfstream is like

a 67 Corvette 427 with dual quads and a big cam. It goes like

lightning, and creates it's own thunder.

|

|

|

|

|

|

Not all of the DC G III's have EFIS. The big CRT's are nice to display FMS information, but they don't make or break the flight. The Gulfstream III is really the same as a G II-B that is a little bit longer and has a cockpit with a modernized look It does have a different windshield that results in a reduction in cockpit noise. Behind the fancy new switches and displays, the two airplanes are about the same, except in the case of the "AC" G III's. They have a different electrical system, the same one that wound up in the G IV. Some like it better, some don't. The "AC" airplanes will have their own study guide. I present it this way because one who is studying for an oral on one airplane needs to concentrate on that one machine, without having to sort out the differences until a bit later.

S t u d y G u i d e

|

|

Gulfstream III

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weights

| Max Ramp Taxi Weight |

|

| Max Takeoff Weight |

|

| Max Landing Weight |

|

| Max Zero Fuel Weight # 300 - 426

# 427 & Sub OR earlier with ASC 70 |

44,000 lbs |

The above weights are maximum certificated limits. The actual maximum weights for a particular flight may vary due to the performance limitations. If the aircraft can not meet the required "Takeoff Field Length" and "Climb" limitations, (engine out climb performance), the maximum takeoff and/or landing weights are reduced such that the requirements are met. See the performance charts in the AFM for details.

Speeds

| Vmo / Mmo |

|

| Va |

|

| Vfe 10 Deg

20 Deg 39 Deg |

220 kts 170 kts |

| Vlo

Vle Emergency Extension |

250 kts / 0.70 Mach 175 kts |

| Vmcg

Vmca |

100 kts |

| Mach Trim Inop |

|

| Windshield Wipers |

|

Altitudes & Misc.

| Max Alt T.O. & LDG |

|

| Max Enroute Altitude

Max Altitude Flap & Gear |

20,000 ft |

| Min Temp T.O. & LDG

Max Slush Max Water |

0.75 inch 0.50 inch |

| Max Temperature

Abv 10,000 ft |

ISA +30 C |

| Min Temp SL - 3,500 |

|

| 3,500 - 5000 Linear |

|

| 5,000 - 10,000 |

|

| 10,000 - 35,000 Linear |

|

| Above 35,000 |

|

| Max Demonstrated X-Wind |

|

| Max Runway Slope |

|

| Max Tailwind Component T.O. & LDG |

|

| Load Factor Limit

Flaps Up Flaps Extended |

2.00 G |

Turn Clearance Limits

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spey Mk 511-8 Engine Limitations

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Above 30,000 ft, it is possible to exceed the engine RPM limits without exceeding the maximum recomended temperatures. You will find that it is the N2 that you must watch at high altitudes, as it is the one that will be the limiting factor.

Engine Oil System Limitations

| Min / @ Max Continuous |

|

| Min / Idle |

|

| Min To Complete Flight @ Max Cont. |

|

| Min To Complete Flight @ 92% N2 |

|

| Min To Complete Flight @ 84% N2 |

|

| Min To Complete Flight @ 52% N2 |

|

| Max Oil Temp |

|

| Max Transient Oil Temp / 15 Min |

|

| Min Oil Temp for Start

Min Oil Temp Above Idle |

-30 C |

|

|

The flight controls on the G III are cable driven with hydraulic boost.. They are powered by both the "Combined" and "Flight" hydraulic systems. Each of the systems provides 1500 psi to the flight control servo actuators. When the landing gear or flaps are extended, the combined system pressure increases to 3,000 psi. If one system fails, the remaining system pressure increases to 3000 psi. Failure of one hydraulic system therefore, does not result in a loss of control effectiveness.

Ailerons

The hydraulically boosted ailerons provide roll control. Either or both hydraulic systems will power the ailerons. Roll control is enhanced by the flight spoilers. When one of the ailerons is deflected up, the two outboard speedbrake panels on the same wing will extend, reducing lift and increasing drag on that side. The speedbrake panels on the side of the down aileron remain stowed. A bungee connects the spoiler mixer and aileron on each side so that the ailerons and spoilers can be moved regardless of the status of the the other. Roll trim is provided by a trim tab located on the left aileron. The aileron trim tab is set with a manual trim wheel in the cockpit. No electric stuff here!

Elevator

The Gulfstream III is equipped with a moveable stabilizer, elevator, and elevator trim tab system. The elevator is hydraulically boosted. Elevator trim adjustments are made with the manual trim wheel in the cockpit, or electrically from the control yoke. The stabilizer is automatically adjusted when the flap setting is changed in order to compensate for changes in trim caused by flap extension and retraction. The stabilizer is moved via a gearbox in the tail. The flap gearbox is connected to the gearbox in the tail. The stabilizer position is indicated by a gauge within the flap position indicator. If the stabilizer does not position itself properly with each change in flap setting, return to the previous setting and go to the checklist. The aircraft may be landed safely with the stabilizer out of trim, however, much higher than normal control forces may be required, as the trim will not be as effective.

Rudder

The rudder, like the rest of the flight controls on the Gulfstream,

is hydraulic. Rudder trim is provided by redefining the neutral position

with the rudder trim wheel in the cockpit. The maximum rudder travel

is 22 deg each side of center. The rudder may be trimmed 10 units,

or 7.5 deg either side of center. The yaw damper is a full time system,

powered by the "Flight" hydraulic system. It has 3 deg of authority

each side of wherever the trim and pilot input would place the rudder.

If the "Flight" hydraulic system fails, the yaw damper is inop.

The rudder on the G III is equipped with a single

and a dual load limiter system. These systems limit the forces applied

to the rudder in order to avoid structural failure of the tail at high

speeds. This single rudder load limiter system limits hydraulic pressure

to a maximum of 2650 psi to the rudder actuator to avoid excessive loads

on the aircraft at high speeds. The dual load limiter system further

limits the pressure to 2250 psi. If only one of these two systems

is operable, and you have an MEL for the aircraft, you can fly.

Each rudder load limiter system has it's own indicator light, an

amber one for the single rudder load limiter system, and a green one for

the dual rudder load limiter. Before start, the amber light should

be on. Only after both engines are running, the amber light will

go out, indicating that the single rudder load limiter system is working.

When the combined and flight hydraulic systems are operating, the dual

rudder load limiter may be checked. This is done by slowly depressing

one rudder pedal to the floor, and looking for a green light to illuminate

at full rudder deflection. Now press the other rudder pedal to the

floor, and the green light should illuminate again, indicating that the

rudder has reached it's mechanical stop, and the dual rudder load limiter

is in fact limiting the pressure. If you get the green light in one

direction but not the other, check the rudder trim and verify that it is

centered. If not, center the rudder trim and repeat the test.

It will most likely work the same on both sides now.

Flaps

The flap system is hydraulic. Flaps may be

extended to 10 deg, 20 deg, and 39 deg with the normal system. The

alternate flap control system can be used to extend or retract the flaps

to any setting between 0 deg and 39 deg. The flaps may be operated

by "Combined", "Utility", or "Aux" hydraulic systems. When the flaps

are moved, the stabilizer is repositioned via a gearbox depicted below..

|

|

|

|

|

|

Because the system changes the angle

of incidence of the horizontal stab, it minimizes trim changes during flap

extension and retraction. Flap asymmetry protection is provided via

electrical signals from the outboard flap jackscrews. The flaps system

will stop if there is 1/4 inch or more difference in the linear travel

of the flap actuators. A torque limiter prevents damage to the system

in the event of a jammed mechanism or an attempted extension at excessive

airspeed. You can, however, damage the flaps by accelerating to an

excessive airspeed after the flaps are already extended. Because

they are mechanically extended by hydraulically driven jackscrews, they

do not retract prior to structural failure. A flap asymmetry will

not reset until it is fixed. If flap movement is arrested, it is

either loss of hydraulics, flap asymmetry, or torque limiting. If

it was torque limiting, slow the airplane down to within the limiting speed

for the flap setting you tried to get. Retract the flaps to the previous

setting, then re-extend at the proper airspeed. If this restores

flap operation, it was in fact the torque limiting system just doing it's

job. The airplane flies just fine if you stay clean until around

200 knots. Extending the flaps at less than the limiting speeds will

minimize the unwanted pitch activity during flap extension.

In the event of unwanted flap movement, the flaps

may be stopped, and the flap selector disabled by a switch on the copilot's

lower arm ledge. With this switch activated, the flaps are moved

by the emergency flap control. Any setting between zero and full

may be selected. You still have flap asymmetry protection in the

emergency mode.

Max Flap Extension Speeds

|

|

|

|

|

|

|

|

|

Flight Spoilers

All G II's and G III's have six spoiler panels on the wing. They are referred to as 4 and 6 panel systems. This addresses the fact that on the "4 panel" airplanes, the inner two panels only extend when ground spoilers are deployed. The outer 4 panels extend when speedbrakes are selected, and all extend in the ground spoiler mode . The "6 panel" airplanes use all of the spoiler panels in flight, but only extend them to 26 deg as opposed to the 43 deg deployment on the 4 panel system. In a turn, the spoilers on the lower wing will extend to 55 degrees in conjunction with full aileron deflection. Gulfstream III,s # 300 thru 384, and # 386 & 389 have the four panel system. These airplanes are equipped with the Ground spoiler deact handle. Numbers # 385 and higher, except 386 and 389 have the 6 panel system, and thus do not have the ground spoiler deact handle. The Flight Spoilers / Speedbrakes are powered by both the "Combined" and "Flight" hydraulic systems. Speedbrakes may be extended with up to 20 deg of flaps. Spoiler / Speedbrakes may not be deployed in flight with the flaps more than 20 deg, or with the Landing Gear extended. The Flight Spoilers also assist in roll control, as they operate selectively with the ailerons. A bunge allows aileron movement in the event the spoiler is stuck.

Ground Spoilers

The ground spoiler system uses the same spoiler panels as the flight spoilers. It merely extends them to 55 degrees, instead of the 26 or 43 degrees, depending on the system, available in flight. The ground spoilers may not be armed without a successful nutcracker test after landing gear extension. There is an easy way to figure out if you have a four or six panel airplane. The six panel airplanes do not have a ground spoiler deact handle. By serial number, the six panel airplanes are: G III # 385, 387, 388, and 390 and subsequent as well as any G III incorporating ASC 50. Notice that with the 4 panel system, the only time that the two spoiler panels closest to the fuselage extend is when the ground spoilers are deployed. With the 6 panel airplanes, the inboard 2 panels extend with speedbrake application, but not in conjunction with aileron deflection. The six panel system uses the inboard panels for speedbrake and ground spoiler deployment only.

Four and Six Panel Spoiler / Speedbrake Systems

|

|

|

|

| Max Aileron,

0 Speedbrake |

|

|

| 0 Aileron

Max Speedbrake |

|

|

| Max Aileron

Max Speedbrake |

Up wing 43 deg |

Others 26 deg |

| Auto Ground Spoilers |

|

|

Nosewheel Steering

Ground steering is provided by a hydraulically actuated steerable nosewheel. The nosewheel may be steered 82 degrees each side of center. The nose steering is powered by the "Combined" or the "Utility" hydraulic systems. In the event those systems are inop, differential braking may be used for directional control on the ground. In order to use differential braking to steer, you must turn the nosewheel steering system off. This is done with a red guarded switch located just forward of the tiller. The nose steering system is disabled unless the nut crackers are in the ground position. Loss of Main DC Bus power has the same result as turning the nosewheel steering system off.

Brakes

The normal braking system provides braking with all of the main gear wheels. The main wheel rotation is arrested during gear retraction. The combined hydraulic system provides 250 pounds of hydraulic pressure to the brakes during the gear retraction cycle in order to stop main wheel rotation. An anti-skid system provides skid protection during braking with the normal system. This includes protection if the brakes are applied prior to touchdown. Anti-skid does, however, require Main DC Bus power. The parking / emergency brake is powered by an accumulator. Use of the emergency brake system usually blows the tires, as it is almost impossible to modulate, and locks the main wheels.

Autopilot

The SPZ-800 autopilot was installed on all of the G III's,

as well as G II # 220 and # 239 and later. The SPZ 800 is an

integrated Auto-Pilot / Flight Director, or Flight Guidance System.

The Sperry auto pilots are pretty good units if you look at the SP 50's

and the SPZ 500 or 550 series and later. I have, however, always

wondered why Sperry insists on placing the glideslope indicator on the

wrong side of it's ADI and HSI units. A word of warning: Do

not develop too much confidence in any gadgets in the airplane. Remember,

these machines usually do what you tell them, not necessarily what you

want them to do. I sat and watched one fellow descend to 400

feet AGL 20 miles outside the Outer Marker on an ILS approach. His

excuse was that the flight director made him do it. It was he, however,

who programmed it. Things like that don't just happen to stupid people.

A good pilot having a bad day can suffer the same fate. This guy

was lucky that his actions resulted in nothing more than a "Pink Slip"

"Why did it do that?" is something most pilots have

said from time to time. Most auto pilot errors are due to flawed

programing by the crew, but not all of them. Use the bells and whistles,

but keep one eye on the raw data just to make sure. Paranoia is only

sound thinking when the world is truly conspiring against you.

|

|

|

|

|

|

| Above Vmo/Mmo |

| Below 1.2 Vs |

| Below 42,000 lbs and CG aft of 43% MAC |

| Auto-Pilot self test prohibited in flight |

| Mach Trim test prohibited in flight |

| No F/D VOR approaches without F/D computer mod. |

| Yaw Damp Inop - Minimum 200 kts or below 28,000 ft |

| No Yaw Damper 1 Eng Inop abv 250 kts or 35,000 ft |

| Mach Trim Compensators Inop

Dispatch - 0.75 Mach & 20,000 ft Inflight Fail - 0.75 Mach |

| AOA - Both required for flight |

|

|

All of the Gulfstream II and III aircraft are powered by two Spey Mk 511-8 engines. These engines produce 11,400 pounds of thrust each. The Spey Mk 511-8 is a twin spool axial flow Jet Engine. The LP compressor, (N1 or Fan) is a 5 stage compressor. Some of the air from this LP compressor is routed around the engine core, and provides thrust. The rest of the LP air is ingested into the HP or N2 compressor. The N2 section has 12 compressor stages. Behind the compressor sections is the combustion chamber, then the HP turbine, and finally the LP turbine. The HP and LP turbines drive their respective compressor sections.

Percent vs RPM

|

|

|

|

|

|

Accessories mounted on the engine include oil pumps,

high pressure fuel pump, a hydraulic pump as well as alternator and generator

for each engine. These are driven by the HP or N2

section. The engine oil is cooled by fuel via a fuel / oil heat exchanger.

It heats the fuel and cools the oil. Oil pressure indications are

provided by an AC powered gauge and a DC powered low pressure light (Idiot

Light) for each engine. There is an engine oil replenishing system

installed on Gulfstream Jets. Engine oil may be serviced only on

the ground.

Variable inlet guide vanes, and farther back, a

surge bleed valve on the 7th compressor stage are installed to stabilize

the engine idle, prevent compressor stalls, and optimize the engine acceleration

characteristics. A malfunction of the surge bleed system will result

in unstable idle, poor acceleration, and compressor stall in many instances.

|

|

|

|

TVI

Vibration is monitored in the engine with the TVI

or Turbine Vibration Indicator system. This system allows the crew

to monitor the engine vibration. This can alert the crew of impending

malfunction or failure of the rotating engine components. Some vibration

is normal, however a change in vibration level may indicate impending doom

for the engine. See the chart below.

|

|

|

| Increase of 1.0 or more during steady state operation | Slowly close thrust lever & observe vibration during deceleration. Make an note of the maximum value. If less than 3.0 (3.5 between 67% and 74% N2), restore power and monitor engine instruments. |

| A sudden increase of 3.0 (3.5 between 67% and 74% N2) | Perform engine shutdown if situation permits. Monitor engine warning systems. |

| During start, Increase of 3.0 or more. | Abort the start. |

| During shutdown, Increase of 3.0 or more. | Record incident and have engine inspected. |

Fuel Heat

An automatic Fuel Heating system is installed on these engines. This is to prevent any ice formation in the engine fuel system. The fuel is heated by P3 bleed air, and monitored by fuel temperature gauges in the cockpit. These gauges are powered by the essential DC bus. Some fuel heating does result from the fact that the hydraulic systems have heat exchangers in the hopper tanks, however the intent of these is to cool the hydraulic fluid. The fact that the fuel is heated a small amount is not important.

Top Temp Control

A temperature control and limiting system is installed

on the Spey 511 Mk-8 engine. This system, if on, will prevent a TGT

overtemp. The temp control amplifier is powered by the 115 Volt AC

instrument Inverter Bus. The Top Temperature Control System is to

be ON except in the event the system fails.

|

G III / DC - Ground use Only |

The great thing about the APU on the Gulfstream is

that it will allow you to start the engines and go someplace, instead of

just sitting on the ramp. The APU on the G III / DC model is for

ground operation only. It can provide air for engine start, or air

conditioning, as well as AC electrical power. Some of this AC is

converted to DC with the Emergency TR to power the DC system on the ground,

or in flight in the event of a problem with one or both DC generators..

The DC can then power the inverters, providing constant frequency AC.

So, in a round about way, the APU can power the entire airplane on the

ground. If you have the 300 Amp TR, you have plenty of DC for

the task, unless you get stupid with an excessive number of boost pumps

and landing lights. The 200 Amp TR is more than enough if you monitor

the amp gauge, and temporarily disconnect one battery during the initial

charging after APU start. You may not need to do this very often,

but be aware.

|

|

|

|

To start the APU, make sure the Main and Essential

DC Busses are powered. It can be started when only the Ess DC Bus

is powered, but problems may result if you attempt to use the APU air.

Turn on the APU Master Switch. Wait for the Low Oil Pressure light

to illuminate, indicating that the APU door is open. Press and release

the start button, and wait. When the APU RPM is stable at 100%, turn

on the Alternator. Check that both AC busses are powered, then select

the Emergency to Main & ESS. Check that the DC Volt Meter reads

at least 26 Volts. The DC Emergency Feeder light should be illuminated,

indicating that the emergency TR is powering the DC Bus/Busses as desired.

The APU Air must be turned on if you wish to do

anything really festive, like start the engines or use the heating / air

conditioning system. Do not run the engines much above idle with

the APU Air Valve Open, as this is not good for the APU.

To shut down the APU, turn off the Air and Alternator,

let the temperature stabilize, then press and release the "Overspeed" test

switch.

Note: Performing a "Nut Cracker" test with the APU

running will shut it down, as the APU will think that the airplane has

just become airborne. I learned this from experience. The bright

side is that I was the only occupant of the aircraft at the time and therefore

did not have to explain my mistake. The APU is a ground only item

on the G-III / DC aircraft.

|

|

Engines / APU

The engines and have continuous wire fire detection

loops in the engine compartments. When heated to their alarm value,

they will cause the engine fire warning system to activate. The respective

left or right ENGINE FIRE lights will illuminate. On # 173 &

Sub and aircraft with ASC 152, fire bell will sound. Press

the "Fire Bell Mute" button to cancel the bell. The fire may be extinguished

by pulling the respective fire handle, and discharging one or both of the

engine fire bottles. Their are two engine fire bottles, each containing

4.5 pounds of Bromotrifluromethane and about 600 psi of nitrogen

to disburse it. Either or both bottles may be discharged into the

selected engine.

|

|

The APU fire warning is provided by a thermal switch. The APU fire bottle is like the engine fire bottles, only smaller. It contains 2.5 pounds of the extinguishing agent, and the 600 psi nitrogen to distribute it. The APU fire bottle may be fired by lifting the guard and moving the switch. Any fire bottle that is discharged must be removed from the airplane, serviced, and reinstalled. The engine and APU fire detection systems are not part of the Master Warning System.

Note: If you get a fire warning, and perform the appropriate procedure, test the fire detection system after you believe that the fire has been extinguished. If the system won't test, the fire detection loop may have been damaged. In this case, you don't really know if the fire was actually extinguished.

Electrical

Overheat warning is provided for the generators, alternators, TR's, radio rack, and inverters. Some of the warning lights serve two items, such as a TR and an Inverter. These require some diagnosis. Refer to the checklist. The E and B inverters and the B inverter's TR have an auto shutoff feature, as they are located in the radio rack inside the airplane. When the B Inverter shuts down due to an overtemp, it also pops the breaker for the bus it was powering. If one bus caused both it's own inverter and the B Inverter to overheat, the problem is most likely on the bus.

Hydraulic

Overheat warning is provided for the Flight and Combined, systems, and the Aux hydraulic pump. These systems do not incorporate any automatic features to deal with the problem. Consult the checklist for the appropriate procedure.

Pneumatic

The wings, tail compartment, bleed air manifolds,

aft compartment, and bootstrap unit are equipped with overheat warnings.

On the ground, the bootstrap unit will shutdown automatically in the event

it overheats. In flight, the bootstrap unit will only give you a

warning, and must be shut down by the crew. Selecting either Emergency

Pressurization or Ram Air will shut down the bootstrap unit. Emergency

pressurization air is available from the LP compressor on the right engine.

The remainder of the warnings must be handled by the crew.

|

|

The G III Fuel System is simple. Fuel is stored

in the wings. Each wing tank has a "hopper" tank that is kept full

with ejector pumps and gravity. Four DC electric fuel pumps provide

fuel pressure to the engine driven fuel pumps. Warning lights will

illuminate when the hopper tank has 675 pounds of fuel or less. This

amounts to between 20 and 25 minutes at 200 knots IAS at 5000 MSL, or about

50 miles to dry tanks.

Two of the fuel pumps are designated as "Main",

and two as "Alternate". They are in fact identical. They are

located in the main wheel wells. Normally, all four pumps are on.

If one pump on a given side is turned off, the other pump can supply ample

pressure. In the event that the operating pump fails, and the failed

pump's switch is in the on position, the other pump on that side will come

on. The main fuel pumps are powered by the ESS DC bus. The

alternate fuel pumps get there power from the MAIN DC bus.

You may supply fuel to either or both engines from

either tank by opening the crossfeed valve and switching the fuel pumps

off on the side from which you do not wish to feed. An intertank

valve is also installed, allowing fuel to gravity flow between the tanks.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The airplane burns about 5,00 lbs the first hour,

3,500 lbs the second hour, 3,300 lbs the third hour, then 3,000 lbs per

hour thereafter. Low altitude holding requires 4,000 lbs / hour fuel

flow. This gives you 7 hours range with an hours worth of holding

fuel, or and hour and 15 minutes reserve according to the regulations.

This will take you more than 3,000 nautical miles at normal cruise.

Use of long range cruise will result over an hours worth of additional

flight time. I know of flights of 8 hours duration that landed with

legal fuel reserves. The G III is quite an airplane. Thank

God it has a bathroom.

|

|

The Gulfstream III hydraulic system uses skydol. It has two engine driven pumps, an electric aux pump, and a utility pump that is driven by the "Flight System". This "Utility Pump" is a hydraulic motor, (driven by the flight system) connected to a hydraulic pump that can pressurize the "Combined System" except the flight controls in the event that the combined system pump, or the left engine were to fail. There is no fluid transfer between the flight and combined systems. If the failure of the combined system includes loss of the fluid, the utility pump will not have any effect, as there is nothing for it to pump! The combined and flight hydraulic systems have heat exchangers located in their respective fuel hopper tanks in order to cool the hydraulic fluid. These have nothing to do with the "Fuel Heat" system which is located in each engine's nacelle.

Combined System

The "Combined System" is powered by a hydraulic

pump on the left engine, or in the case of Combined System pump,

or engine failure, the Utility Pump. The utility pump is driven by the

Flight System. The electric "Aux Pump" can power 5 items only.

See the chart below.

Flight System

The "Flight" System" is powered by an engine driven

hydraulic pump located on the right engine. It's normal operating

pressure is 1500 PSI. It will operate at 3000 PSI if the combined

system pressure drops below 800 psi. This is to increase the pressure

to the flight controls, and to enable the flight system to power the Utility

Pump.

Utility Pump

The Utility pump is a hydraulic pump that pressurizes

the Combined System when it's own pump is not putting out sufficient pressure

for whatever reason. Operation of the utility pump requires at least

2,200 psi flight system pressure. The Utility pump can drive

all of the combined system items except the ailerons, elevator, rudder

and flight spoilers. In the event it is necessary to use the utility

pump, those items are operated by the flight system. If the flight

system does not work, the utility pump won't work either, as the utility

pump is driven by the flight system in the first place!

Aux System

As you can see from the table below, the aux system,

in normal operations, is used on the ground. It allows you to extend

and retract the landing gear doors during the preflight, closes the cabin

door, and provides pressure so you can set the parking brake. It

also operates the Flaps and Brakes on the ground or in flight.

|

|

|

|

System |

|

| Ailerons | Ailerons | |

| Elevator | Elevator | |

| Rudder | Rudder / Yaw Damper | |

| Flight Spoiler / Speedbrake | Flight Spoiler / Speedbrake | |

| **Ground Spoilers | **Ground Spoilers | |

|

|

Right Thrust Reverser | |

|

|

Utility System Motor | |

| Ground Spoilers | <<<--- | Right Thrust Reverser |

| Nose Steering | <<<--- | Flight Sys Reservoir Press. |

| Thrust Reversers | <<<--- | |

| Stall Barrier | <<<--- | |

| Windshield Wipers | <<<--- | |

| Combined Sys Reservoir Press. | <<<--- | |

| <-Aux Pump | ||

| Landing Gear | <<<---Note: Gear on ground only! | |

| Pedal Brakes | <<<--- | |

| Flaps | <<<--- | |

| Parking Brake | <<<--- | |

| Cabin Door (Close only) | <<<--- |

** Six Panel System only. On the four panel system, the ground spoilers can be powered only by the Utility system, or by the flight system pressure that is downstream of the one way check valve. That check valve is installed to prevent the utility pump from powering the combined system flight control servoactuators.

Note: Use of the Aux Pump to operate the Landing

Gear on the ground is limited to the landing gear doors only. The

gear doors are opened on the ground for preflight, and to keep condensation

from accumulating in the main gear doors. If you leave the airplane

in an environment where the temperature goes below freezing, any water

that may be in the main gear doors can freeze, and may interfere with landing

gear operation if it remains during gear retraction, or cause damage on

the ground if a chunk of ice falls out and hits something.

|

SN # 300 thru 356, # 358 thru 401 and # 875 |

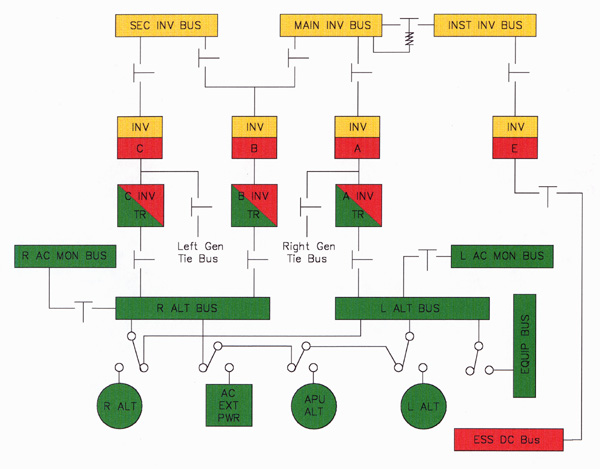

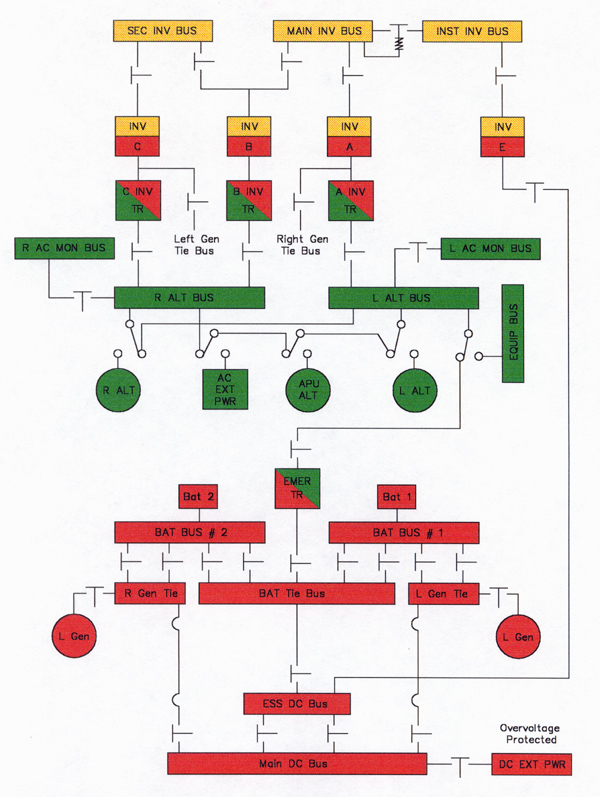

The electrical system on the Gulfstream III may look complicated at first glance, but it is not. It consists of 2 batteries, two 300 amp brushless DC generators, and two variable frequency (wild AC) 115 Volt 20 KVA alternators plus an APU alternator of the same capacity. Not counting the APU alternator, because it can't be used in flight, the Gulfstream III has 2 DC generators and 2 Alternators. Also they have 4 inverters to make constant frequency AC from DC, and 4 Transformer / Rectifiers to make DC from AC. The bottom line is, as long as you have at least one of the four electrical generating devices operational, you will have at least the minimum electrical power needed to fly the airplane. In the Gulfsteam, one out of four ain't bad!

Overview

In general, the DC system powers most of the electrical

components on the airplane. The alternators provide power to heat

the windshields, power some interior lighting, and to power the TR's

that produce the DC that powers the inverters. It may sound complicated,

but a peek at the electrical schematic will make it a bit less confusing.

The inverters supply the 400 hz AC that is needed by the gyros, avionics,

and flight guidance system. The "E" (instrument) inverter is powered

by the ESS DC bus. It is only needed when the Main Inv. Bus is not

powered by the A or B inverter, or by the left generator tie bus through

the use of the Inv Alt Pwr, or "Skip" switch. The "A" and "C"

inverters are powered by their respective TR's, but can also be powered,

if desired, by the DC system through the use of the INV ALT PWR switches.

These are also refereed to as "Skip" switches.

The Emergency TR is powered by the left alternator

bus. This bus should be powered if any one of the three alternators

is operating. The emergency TR can power the ESS DC bus, and both

the MAIN and ESS DC busses as desired. When the airplane is on the

ground without the engines running, the ESS TR powers the DC system.

This is normal.

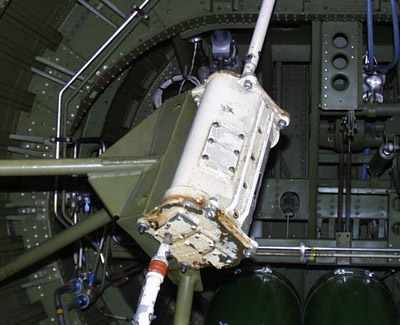

Emergency Transformer-Rectifier

The Emergency TR is installed in the tailcone of

the airplane. It is rated for 200 amps DC output. If ASC 111

is incorporated, the maximum output is 300 amps. The emergency

TR is used to power the aircraft's DC system during ground operations while

using the APU alternator or external AC power.

On airplanes incorporating ASC 155, the TR, when

selected to ESS DC, powers the Essential DC Bus even if the battery switch

is turned off, or fails. If the battery switch is then selected to

normal, the Emergency TR powers both the main and essential dc busses.

Constant Frequency AC System

The constant frequency AC system is controlled by

the switches below. Each AC bus has it's own 3 position switch.

Normal, Off, and Standby or Emerg. are the switch positions. With

all three switches in NORM, the A inverter powers the Main and INST Inverter

Busses, the C inverter powers the Secondary INV bus, and the B inverter

powers nothing. As long as the A or B inverter is powering the Main

Inv. Bus, the Main and Inst AC busses can almost be considered one bus,

as they are connected. This remains so as long as either the A or

B inverter is powering it. If, however, the E inverter is powering

the Emergency Instrument Bus, the relay between the two busses opens and

the E inverter powers ONLY the Instrument Inverter Bus.

If the main or secondary inverter bus switch is selected to standby, the

B inverter powers that particular AC Bus. The B inverter can power

the Main OR the Secondary AC bus, never both at the

same time. If both the Main and Sec bus switches are in standby,

the Main gets the power.

|

|

|

AC

Variable frequency AC is provided by the two ships alternators,

and on the ground only, the APU alternator. Constant frequency AC

is provided by converting the variable frequency AC to DC, with a Transformer

/ Rectifier or "TR". The then "TR's" DC output powers inverters

that produces the constant frequency AC. There are four inverters

in this system. The "E" inverter can power only the Instrument AC

Bus. The "C" Inverter powers only the Secondary AC Bus. The

B inverter can power the Main, or Main and Instrument AC Busses, OR

it can power the Secondary AC Bus, but not both. The A inverter can

power the Main AC, or the Main AC and the Instrument AC busses. The

E and B inverters are in the radio rack, and have thermal protection that

will shut them down if they overheat. The A and C inverters have

overheat warning lights, but no auto shutdown protection. If the

TR's feeding the A or the C inverters fail, those inverters may be powered

by the DC system through the use of the "Skip" switches. The inverters

overheat warning tells you that the respective inverter or the "TR" has

overheated. Switch inverters and let things cool for a minute, then

if you wish to diagnose the problem, turn the inverter back on and use

the "Skip" switch. If the fault does not recur, it was most likely

the "TR", and if it does, it was the inverter that was the problem.

|

|

GO Inverter & Constant Frequency AC Bus Check

DC Generators

The DC generators on the G III are really just huge

slightly more sopisticated cousins of the alternators on your family car.

They really are alternators, producing AC power, but incorporate "Diodes"

to convert this AC into DC electric current. The end result is that

the device supplies DC, and is therefore called a generator. They

are rated at 28.5 volts and 300 amps output. If both are operating,

you can draw 300 amps from each of them. If one has failed, you are

limited to 250 amps from the remaining generator.

These generators have, in addition to the normal

electrical system L GEN and R GEN failure lights, three warning lights

that alert you to problems with the generator.

FLD :BRG - Failed Bearing - These generators have both primary and auxiliary bearings. This is basically one bearing inside another. If the primary bearing is failing, and you have an MEL, you can operate for a maximum of 30 hours until repairs must be made. You are limited to 250 amps during this period.

O.V. - Over Voltage. Alerts crew that the generator trip was due to over voltage of 31 volts or more. You may attempt to reset this one time only. If it fails again, trip the generator and leave it off until repaired.

F.D. - Failed Diode - One of the diodes in the generator has failed, either open or shorted. By accessing the voltage regulator and placing the emergency switch to OVERRIDE, you may be able to use the generator for 30 hours at a maximum of 250 amps.

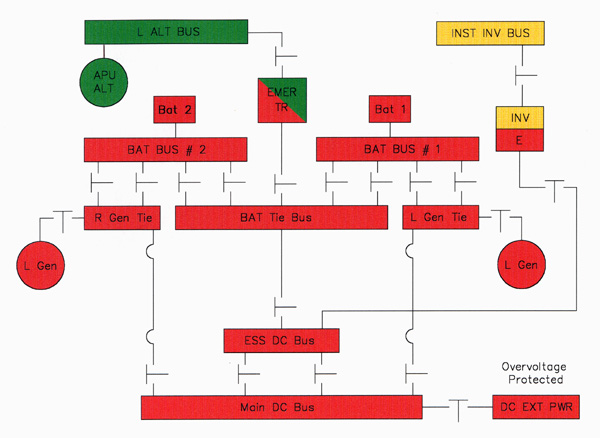

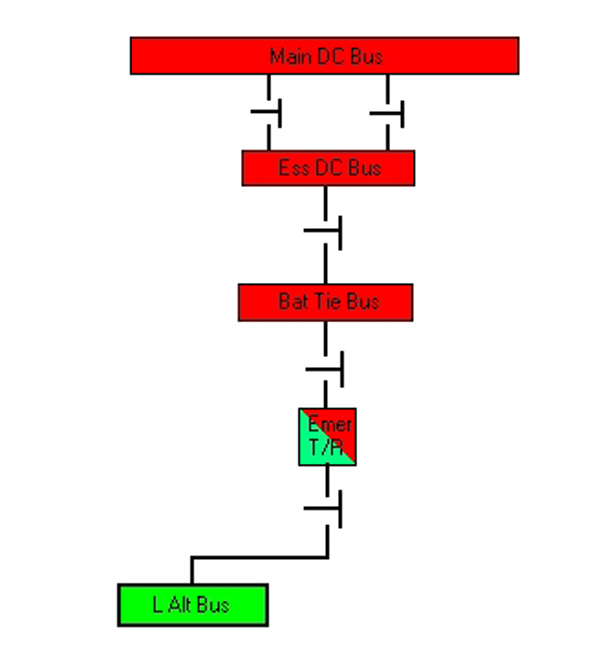

DC System

DC is supplied by either or both of the brushless DC generators,

and / or by the Emergency "TR". The Emergency "TR" is powered

by any one of the ships alternators through the left alternator bus.

The DC power is distributed by two busses, Essential and Main. Loss

of one DC generator is not a problem, as you merely revert to "Split Buss"

operation to reduce the load on the remaining generator.. Place the

TR switch to ESS, and Bat switch to Emergency. Now, your remaining

DC generator powers the main DC Bus. The Emergency TR powers the

Essential DC Bus, and keeps the batteries charged. The Emergency

TR is powered by the left AC bus. When you select the Emergency

TR, the left AC equipment bus becomes unpowered as indicated in the previous

electrical schematic.. Operation of the Emergency TR is illustrated

below. With the failure of both DC generators, and at least one alternator

on line, the Ess DC Bus can be powered by the Emergency TR. You can

also power the Main DC Bus, but be cautious not to overload the TR or the

alternator. The 300 amp TR is not installed on all airplanes, and

the alternator is limited to 53 amps for continuous operation.

|

|

|

|

|

Normal during Ground Operation |

The Emergency TR can power the Ess DC Bus, or both the Ess and Main DC Bus, as selected by the crew. The 200 Amp Emergency TR needs a bit more monitoring when the batteries are charging at a high rate. Disconnecting one battery reduces the load on the TR by as much as 50 to 100 amps.

GO

Battery Integrity / DC Systems Check

|

|

|

Note: The DC G III's also include # 875 and exclude

# 357

One look at the electrical panel and you will have

no doubt

as to which electrical system is installed on your

airplane.

|

|

One Generator & One or both Alternators Operating

Split the bus! Battery switch to Emergency, TR switch to Essential. ESS DC Bus is powered by the TR, and the Main Bus is powered by the remaining generator. Load on the operating generator is reduced. The inverters are powered normally. All busses are powered except the AC equipment bus which is lost whenever the emergency TR is in use. If one alternator is inop, the AC monitor buses will be unpowered as well.

One Alternator & Both Generators Operating

No action required; The alternator busses get power from the opposite alternator bus when their own alternator fails. The AC monitor busses will not be powered. Monitor the alternator load. Windshield heat is a high draw item. In non-icing conditions, it can be shed if speed altitude and humidity permit. One of the inverters may be powered by the DC system through the use of the "Skip" switch if AC load reductin is desired.

One Generator Operating & Both Alternators Failed

Monitor the load on the remaining generator. Inst. Inv. Bus is powered by the E inverter. You will have at least the Essential DC Bus and depending on the DC load, the Main DC Bus as well.

One Alternator Operating & Both Generators Failed

Battery switch to Emergency, TR switch Essential. ESS DC Bus is powered by the TR. If the load on the generator permits, the main DC bus may be powered. The inverter system should operate normally.

Electrical Capacities

| Alternators / Engines | 20 KVA |

| DC Generators

1 Gen Operation |

28.5 Volt / 300 Amps

28.5 Volt / 250 Amps |

| Emergency TR / Standard | 200 Amp |

| Emergency TR / Optional | 300 Amp |

| APU Alternator | 20 KVA |

| Batteries 1 & 2 | 24 Volt / 36 Amp Hour |

|

|

The Gulfstream II-B is certified for flight into known or forecast icing conditions. We will discuss the various Ice and Rain protection devices system by system. The vertical and horizontal stabilizers do not require ice protection. This was determined by flight testing during the aircraft's certification process. All of the Gulfstream's anti-ice systems are powered by the Essential DC system.

Engines

The engine inlet hub fairing, inlet guide vanes,

and the nose cowl are heated by engine bleed air in order to prevent ice

formation. The air is controlled by two engine anti-ice valves located

on each engine. These valves are opened and closed with the "ENG.

ANTI-ICE" switches. Each valve has a separate circuit. To determine

if one anti-ice valve has failed to open, compare the engine anti-ice duct

pressures. The engine EPR pitot probes are heated electrically heated when

engine anti-ice is selected on. On aircraft with ASC 111, the EPR

pitot probes are heated when the Pitot Heat switch is on.

If the anti-ice duct pressures are the same at equal rpm, they are OK.

If they differ by 15 psi or so, and one is below 45 psi, one valve is probably

failed closed. If the pressure is more than 60 psi, a valve has more

than likely failed open. These valves fail to the closed position

when Essential DC power is lost.

|

|

Wings

The wing leading edges are heated with engine bleed

air in order to prevent ice formation. Wing heat is controlled with

two "Wing Anti Ice" switches. Each of theses switches controls it's

respective wing anti-ice valve. This does not mean that you may heat

one wing and not the other. The bleed air ducting downstream of the

wing anti-ice valves is connected by a crossover manifold such that either

Wing Anti Ice switch being turned on heats both wings.

After activating the wing anti-ice system, the wing

leading edge begins to heat. When the respective wing temperature

reaches 100 deg F, the that wing's green light above the Wing Anti Ice

switches will illuminate, indicating normal operation. The temperature

is automatically regulated. If the wing anti-ice controllers fail,

and the temperature reaches 180 deg F, a red L or R WING HT light will

illuminate. You must then turn one or both wing heat switches off

as necessary to extinguish the warning lights. The entire wing anti-ice

system is useable during emergency DC operation, as the CB's are on the

Essential DC Bus.

Windshields

Rain removal is performed with electrically powered

windshield wipers. The left wiper motor is powered by the Ess DC

Bus, and the right is powered by Main DC. The windshields are also

heated electrically. They are heated with power form the right alternator

bus. Windshield heat is for anti-ice and defogging. The windshield

heat is not necessary for bird strike protection on the G III. When

the windshield heat switch is placed in the "ON" position, the windshields

receive electrical power from the "Right Alternator Bus". This bus

can be powered by either of the ships alternators, or the APU alternator

if it is operating. The AC power on the Gulfstream is 3 phase.

Without going into lots of detail, three phase alternators behave like

three alternators, providing 3 wires, and an electrical ground.

The left front and right side windows share the

same temperature controller. The right front and left side windows

do the same. Each controller receives power from two of the three

phases of AC power. A green advisory light illuminates when a specific

window is being heated. The lights may be tested with the warning

lights test button. If a particular light tests OK but does not come

on, it may indicate that the particular window is at the proper temperature

and is not being heated at that moment. If the light remains out

for a long period of time at high altitude, the heat for that window has

probably failed.

Pitot-Static & AOA

The pitot tubes and the angle of attack probes are

electrically heated. The left form the ESS DC Bus, and the right

from the Main DC Bus. When pitot heat is on, the EPR pitot tubes

are also heated. The pitot heaters receive the same power in flight

or on the ground, as long as they are turned on. Do not use them

on the ground for extended periods. Pitot heat is to be turned on

just prior to taking the active runway, and turned off after clearing the

runway after landing.

The AOA heaters, when on the ground, receive only

25% of the power they receive when the aircraft is in flight. They

can and should be turned on after the engine start check is complete, and

left on until shutdown.

Pitot Heat Warning

|

|

|

Angle of Attack

1

2

|

|

|

|

|

|

|

|

Pressurization

The cabin is pressurized with HP bleed air from the N2 compressor section of each engine. If the air-conditioning unit (boot strap) fails, emergency pressurization may be selected. This provides air from the LP or N1 compressor section of the right engine. The pressurization is regulated with one of two outflow valves. The normal outflow valve is electrically operated. It is AC powered in the "Normal" mode, and DC powered in the " manual mode. The second outflow valve is a "Safety Valve", requiring no electrical power whatsoever. This valve provides relief at maximum pressure differential, and vacuum relief, as well as a pressurization rate limiter.

During normal operation, before takeoff, you set

cruise altitude, barometric pressure, destination field elevation and cabin

rate. The system does the rest. Change the barometric pressure

setting if appropriate, and at top of descent, move the switch from "Flight"

to "Landing".. That's it! If manual mode is required, move

the outflow valve as necessary with the manual (DC electric) system.

Go easy, as the valve moves quite fast. A general announcement to

the passengers may keep you from looking like a dummy!

|

|

|

|

Emergency pressurization air comes from the LP bleed port on the right engine. Selecting RAM CABIN AIR closes the air-conditioning valve, causing the airplane to depressurize. Once the cabin has depressurized, the ram air valve opens to ventilate the cabin.

Air Conditioning

The same air that pressurizes the airplane

also provides air conditioning and heating. What a surprise we have

here! The engine bleed air is quite hot, up to 900 deg F when

it comes out of the HP port, and about 400 deg F once it passes through

the precooler.. In order to cool it, there are heat exchangers in

the engine pylons, and a "Boot Strap" unit to further cool the air.

The rest of the industry calls it an "Air Cycle Machine", "ACM" or "PAC",

but Gulfstream insists on being different. In simple

terms, the hot air is cooled, compressed, cooled again, and allowed to

expand, driving the cooling turbine, further reducing the temperature of

the air. This cold air is mixed with warm air to regulate the

temperature. (For more theoretical information, see the "Glossary"

included

in the study guide section of this web site. See "Air Cycle Machine")

If for any reason, like maybe smoke evacuation, you wish to depressurize

the airplane and ventilate it with ram air, you may do so by placing the

"Cabin Air" switch to "RAM". This closes the valve that allows bleed

air to enter the cabin, and after the cabin pressure leaks down, allows

ambient air to ventilate, but not pressurize the aircraft.

Control of the temperature is managed by two selector

switchs and two rheostats on the overhead panel. The switch positions

are "OFF", "AUTO", and "MANUAL" for the CKPT and CABIN, as each have their

own switch. There is a small switch between the temperature control

rheostats. This switch selects the temperature sensor that drives

the "Cabin Temp" gauge. With both switches in "AUTO", the system

works as intended. The cockpit thermostat regulates the temperature

in the cockpit, and the cabin thermostat does the same for the cabin.

When one of the switches is placed in "MANUAL" , that system takes

it's orders from the other controller. This remains true regardless of

the position of the other switch. When a particular system

is selected "OFF", that system drives it's temperature control valve to

full cold. The controller, however, may still be used to regulate

the temperature of the other system should that other system be switched

to "MANUAL". Full cold may be OK in Phoenix in the summer,

but as for Bozeman Montana in the winter, or after about half an hour at

cruise, you will freeze your boss, and he will be unable to sign your paycheck

due to hypothermia.. If you must use the "OFF" position, there are

two valves in the baggage compartment that will enable you to control the

temperature manually. They are located on the left, or aft edge of

the external baggage compartment door. Do not show the cabin attendant

where these valves are. They are for use only by the flight deck

crew and only when both automatic systems have failed.

|

|

|

|

|

|

GO Entire Warning Light System

Note: I will divide these up by system at a later date, but for now, here they are. If you are looking for a specific one, try CTRL F, and type in what you want to find.

Back to: Airplane Driver Home Page