|

|

|

If you see any errors or omissions, or have something usefull to add, please email me at avgroup@socal.rr.com and I will make the appropriate corrections as soon as possible. Improvements in any training material happen most rapidly with feedback from the end user. This site is for your use, let me know how I can make it better.

|

|

|

|

|

A word about Oxygen: Most or all of us have

heard of the Lear 35 that crashed in the North Central U.S. after flying

for several hours with a load of disceased occupants aboard. The

sad thing is that it did not have to happen. A quick preflight of

the Oxygen System would have prevented this tradgedy. Rember, pressure

trapped in the lines can cause the Oxygen Pressure Gauge to read in the

green when the Oxygen Valve is turned off. Check your mask and watch

for a drop in the pressure gauge. Twenty seconds of caution may save

your life.

|

|

| Lear |

|

| Max Ramp Weight

ECR 2173 ECR 2554 or AAK 55-82-3 ECR 2431 or AAK 55-84-6 |

20,750 lbs 21,250 lbs 21,750 lbs |

| Max Takeoff Weight

ECR 2173 ECR 2554 or AAK 55-82-3 ECR 2431 or AAK 55-84-6 |

20,500 lbs 21,500 lbs 21,500 lbs |

| Max Landing Weight

ECR 2432 or AAK 55-84-3 |

18,000 lbs |

| Max Zero Fuel Weight |

|

| Max Baggage Comp. |

|

| Typical Basic Operating Weight |

|

The above weights are maximum certificated limits. The actual maximum weights for a particular flight may vary a great deal due to performance limitations. If the aircraft can not meet the required "Takeoff Field Length" and "Climb" limitations, (engine out climb performance), the maximum takeoff and/or landing weights are reduced such that the requirements are met. See the performance charts in the AFM for details.

Speeds

|

|

|

| Vmo

At or Above 8,000 msl |

350 kts |

| Mmo

FL 370 to FL 450 FL 450 & Above Stick Puller Inop Mach Trim Inop w/o Auto Pilot |

0.79 to 0.81 M 0.79 M 0.74 M 0.74 M |

| Va |

|

| Vfe 8 Deg

20 Deg 40 Deg |

200 kts 150 kts |

| Vlo

Vle |

260 kts |

| Vsb

(Not with flaps when airborne) |

|

| Vmca

Flaps 8 / APR Operating Flaps 20 - APR Inop Flaps 20 - APR Operating |

106 kts 99 kts 101 kts |

| Vmcg |

|

| Nosewheel Steering

Primary Wheel Master |

Authority 45 kts |

| Max Tire Groundspeed |

|

| Max Alt T.O. & LDG |

|

| Max Enroute Altitude

|

41,000 ft |

| Max Alt. Flaps Ext |

|

| Min Temp T.O. & LDG |

|

| Max Temperature @ SL

|

+52 C |

| Max Tailwind T.O/ LDG |

|

| Max Runway Slope |

|

| Max Fuel Imbalance

Enroute |

500 lbs |

| Load Factor Limit

Flaps Up Flaps Extended |

+ 2.0 /- 0.0 G |

Engine Limitations

Without APR

|

|

|

|

|

|

|

|

|

|

|

|

| Takeoff

Transient |

|

|

939 C |

10 Seconds |

| Max Continuous

Max Recommended |

|

|

865 C |

No Limit |

| Max Overspeed |

103.0% to 105.0% |

105.0% |

|

5 Seconds |

With APR

|

|

|

|

|

|

|

|

|

|

|

|

| Takeoff

Transient |

|

|

929 C 939 C |

5 Minutes 10 Seconds |

| Max Continuous

Max Recommended |

|

|

865 C |

No Limit |

| Max Overspeed |

103.0% to 105.0% |

105.0% |

|

5 Seconds |

Engine Oil System Limitations

| Max Oil Temp to 30,000 ft

above 30,000 ft |

140 C 149 C |

| Min Oil Temp for Start |

|

| Max oil consumption / 25 Hours |

|

Systems

|

|

Primary Flight Controls

The ailerons, elevator and rudder on the Lear Jet

are manually actuated by the pilots. Aileron and rudder trim is achieved

with trim tabs on the rudder, and left aileron. These trim tabs are

positioned by electric motors located inside the left aileron and the rudder

it's self. Pitch trim is achieved by changing the position of the

moveable horizontal stabilizer. There are two trim motors that will

do this, a primary, and a secondary. The aileron, rudder,

and primary pitch trim are controlled with a thumb switch on the left side

of the Capt.'s and right side of the Co-Pilot's control yoke. The

secondary trim is actuated by the autopilot, and can be controlled by an

electric switch on the console in the event the primary trim fails.

All Lear Jets have autopilots, although not a very

good ones until you get to the 31, 45, 55 or 60. The ailerons and

elevator may be moved by the autopilot servos, and the rudder is equipped

with a primary and secondary yaw damper. Both yaw dampers are required

for flight although only one may be engaged at a time.

The Lear Jet has two stall warning systems.

They are the same. Both are required for flight. Angle of attack

information is given to the system by two angle of attack vanes located

on the left and right sides of the nose of the aircraft. These vanes

are heated when the pitot heat switch is on. They get hot enough

to burn you, so touch them with caution.

About 7% above a stall, the system warns you with

a flashing stall warning annunciator light, and by activating the stick

shaker. If you ignore the shaker, and continue to increase the angle

of attack, you will then get a "Nudger" that applies an intermittent foreward

push on the stick. At about 5% above a stall, the autopilot pitch

servo applies an 80 pound push on the elevator. If you do not notice

this, you deserve to crash! It is hard to ignore.

There is a "Wheel Master" button just below the

trim actuator on each pilot's yoke. It is a handy little guy.

It interrupts any elevator trim action, deactivates the stick pusher, disengages

the autopilot, and will engage the nosewheel steering if the gear is down.

The trim check very important on the Lear Jet, as the trim system on this aircraft, if not properly set can KILL you within seconds after liftoff. Excuse the lack of tact here, but it's a fact. Perform the trim check prior to takeoff.

Flaps

The flaps on the Lear are hydraulically actuated.

The flaps are controlled in one of two ways, depending on the model Lear.

Lear 55's have preselect where you place the lever in the 8 deg,

20 deg, or 40 deg position, and the flaps extend to the position requested.

If the flaps will not extend, add 30 kts to your approach speed and 30%

to your landing distance. The flaps will operate with pressure supplied

from the engine driven or the electric hydraulic pumps. There is

pressure relief valve in the flap system that will prevent damage to the

flaps if they are inadvertently extended or left down at speeds in excess

of their operating limitations.

Spoilers/Spoilerons

Lear 55's are equipped with spoilers. They

may be deployed up to Vmo / Mmo in flight only when the flaps are retracted.

On landing, they should be deployed just after touchdown. You can

have them deployed by the Auto Spoiler System, or you can just use the

switch like the earlier Lear Jets. They are hydraulically actuated,

and electrically controlled. They have two positions, fully deployed,

and stowed when operating in the "Spoiler" mode.

When the flaps are more than 25 deg extended, the

spoilers will extend on one side or the other to provide better roll control

at approach and landing speeds. In this case they are called "Spoilerons"

The spoiler on the same side as whatever aileron is deflected upward will

match the position of that aileron. This kills some of the lift on

that side, and makes low speed roll control much more effective than on

the 20 series airplanes. Spoilerons require AC power to function.

Nosewheel Steering

The nosewheel steering on the Lear is electric.

It requires both AC and DC to operate. Steering is engaged with the

wheel master switch, or by a "Steer Lock" switch on the left side and right

sides of the foreword instrument panel.. Maximum speeds for use of

nosewheel steering is either 45 knots, or 10 knots, depending on the steering

mode selected, and / or loss of wheel speed input from more than one of

the right three main wheels. See AFM for details.

Landing Gear

Like all other aircraft intended for more than one

flight, the Lear jet has a landing gear. It is extended and retracted

hydraulically, and controlled electrically. It can be extended with

high pressure nitrogen if the normal extension fails. If you extend

the Landing Gear with the nitrogen bottle, you will see three green lights,

and the two inboard gear door red lights, indicating that the gear is down,

but the inboard gear doors are still open. Do not exceed 200 knots

after alternate extension of the gear. As far as the airplane is

concerned, the gear is still in transit, at least from a limitations point

of view.

Brakes

Each main landing gear on the Lear Jet has

two wheels and tires. Each wheel has it's own hydraulic brake, with

anti-skid protection. The brakes on the left gear are controlled

by pressure applied to either of the left brake pedals, and the right brakes

work the same way from the right pedal pressure. The anti-skid system

can relieve the brake pressure on any individual wheel.

The initial brakes on the Lear 55 were woefully

inattiquite. There were situations where you could take off heavier

at high elevations with Flaps 20 deg than at Flaps 8 deg. Why?

Because you were brake energy limited. They did eventualy improve

the brakes, but the first ones were a real departure from the fine engineering

that usually exists in a Lear Jet.

If the hydraulic brake system fails, there is an

alternate brake system that will apply the brakes with high pressure nitrogen.

The same bottle is used for emergency gear extension. The emergency

brake system does not provide any anti-skid, or differential braking capability.

It is a good system, and if you use it with your brain engaged, it works

fine.

** Prior to takeoff, ALWAYS check the 3 Killer Items **

|

|

|

|

Fuel Capacity

Lear 55

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lear 55 ER

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel / Ram Air Temperature Limits

|

|

w/o AAK 55-84-1 |

AAK 55-84-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The fuel system on the Lear 55 is simple, and one

of the most reliable on any aircraft. It consists of two wing

tanks, and a fuselage tank, or in the case of the 55 ER, two fuselage tanks.

The fuel feeds the engines from the wings only. left engine to left

wing, right engine to right wing. All fuel must at some time make

it's way to the wing tank if it is to be used.

The wing tanks each have an electric boost pump,

and a jet pump. The boost pump provides fuel pressure during engine

start, and when selected to transfer fuel between the wing tanks through

the crossflow manifold. The fuselage tank has two electric boost

pumps that are used to fill the tank from the wings, and to transfer the

fuel back to the wings during flight. The fuselage fuel must be transferred

by the pilots.

Wing Tanks

The wing is just a big fuel tank in the shape of an airfoil. It is divided in half by a center rib, separating it into two tanks. Relief valves are installed in the center rib (bulkhead) to prevent tank overpressure during crossflow operations. A crossflow valve is installed in a manifold connecting the left and right wing tanks. This manifold has an electric fuel boost pump on each end, allowing fuel to be transferred from one side to the other when the crossflow valve is open. There is no "Crossfeed". You can not feed, for example, the Left Engine from the Right Tank. You can, however, transfer fuel from the Right Tank to the Left Tank, thereby supplying fuel to the Left Engine. The wings may be fueled through the filler caps located just inboard of each wing tip, or via a single point refueling system if installed.

Fuselage Tank

The Fuselage Tank is installed aft of the internal baggage compartment. It is a bladder type tank. It has two electric fuel pumps that enable you to transfer the fuselage fuel to the wings, such that the fuel may finally make it to the engines. You may fill the fuselage tank by single point if installed, through it's own filler cap, or from the wings with the standby fuel pumps located in each wing center section.

You have 4 options as to how to transfer fuel from the fuselage tank to the wings:

1. Gravity Transfer - Open the transfer valves

after departure and wait. Slow but it works.

2. Normal Transfer - The left fuselage tank

pump transfers fuel into both wings.

3. Aux Transfer - The right fuselage tank

pump transfers fuel into both wings.

4. Rapid Transfer - Both fuselage tank pumps

transfer fuel into the wings.

Aft Fuselage Tank

The optional aft fuselage tank can be filled from the main fuselage tank, or with the (optional) single point refueling system. It's fuel can be transferred into the main fuselage tank. If a single point refueling system is installed, the aft fuselage fuel may be transferred directly into the wings. In the real world, this 360 pounds of fuel amounts to about 15 minutes, or a little over 100 nautical miles at cruise.

Single Point Refueling

The single point refueling system on the Lear 55 is fairly straight foreward. The single point fitting and the Fueling Control Panel are located on the right side of the fuselage just above the trailing edge of the right wing. It don't take a rocket scientist, but there are a few things to remember about this system.

1. In some of the older or unmodified airplanes, the cockpit battery switches must be on. In the newer or modified aircraft, the refueling master switch does the job from the outside.

2. Make sure the system is functioning properly prior to proceeding with the fueling. Check the auto shutoff feature with the two valves closed, and make sure that the fuel vent light remains on during the entire procedure. No light, no single point fueling. Single point fueling without the fuel vent system operating can damage the airplane.

3. If you are adding fuel, but not filling all the tanks to capacity, select "Partial" rather than full. This fills the wings first, then adds fuel to the fuselage tank(s). You want full wings if you are going to add fuel to the fuselage. Otherwise, you may find yourself with an aft center of gravity.

GO

Fuel System Photos

|

|

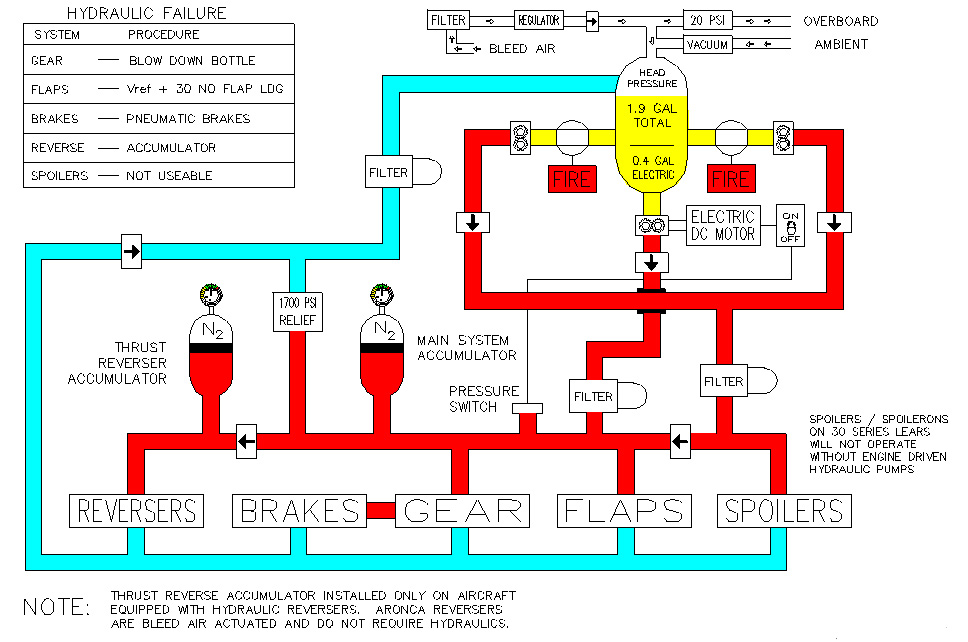

The Lear Jet hydraulic system consist of 2

engine driven, and one electric hydraulic pump, a 1.9 gallon reservoir,

an accumulator (two accumulators if Dee Howard reversers are installed)

and a couple of pressure relief valves. The fluid is 5606 therefore

if you spill some on yourself, you won't wind up looking like you and Michael

Jackson share the same dermatologist. The system operates the landing

gear, normal braking with anti-skid, the flaps, spoilers, and thrust reversers

(except aeronca) if the aircraft is so equipped.

The reservoir is pressurized by bleed air on later

models, and cabin air on earlier Lears. This is to prevent foaming.

The engine driven hydraulic pumps can only access 1.5 of the 1.9 gallons

of hydraulic fluid. The additional 0.4 gallons can be used by the

electric hydraulic pump only. It can extend the landing gear, the

flaps, provide normal braking with anti-skid, but will not operate the

spoilers. The hydraulic thrust reversers have their own accumulator,

and should be useable even with total hydraulic failure. The Aeronca

Reversers are bleed air powered, therefore do not require the hydraulic

system.

The system has two pressure relief valves, one main

system relief valve, that relieves at 1700 to 1750 psi, and one relief

valve in the flap system that relieves about 1650 psi. See "Flaps'

in the flight controls section for more details on this.

With total hydraulic system failure, blow the gear

down, approach at Vref + 30 kts, use pneumatic brakes, and plan on 1.7

to 2.0 times your normal landing distance. T/R's may work!

|

|

|

|

|

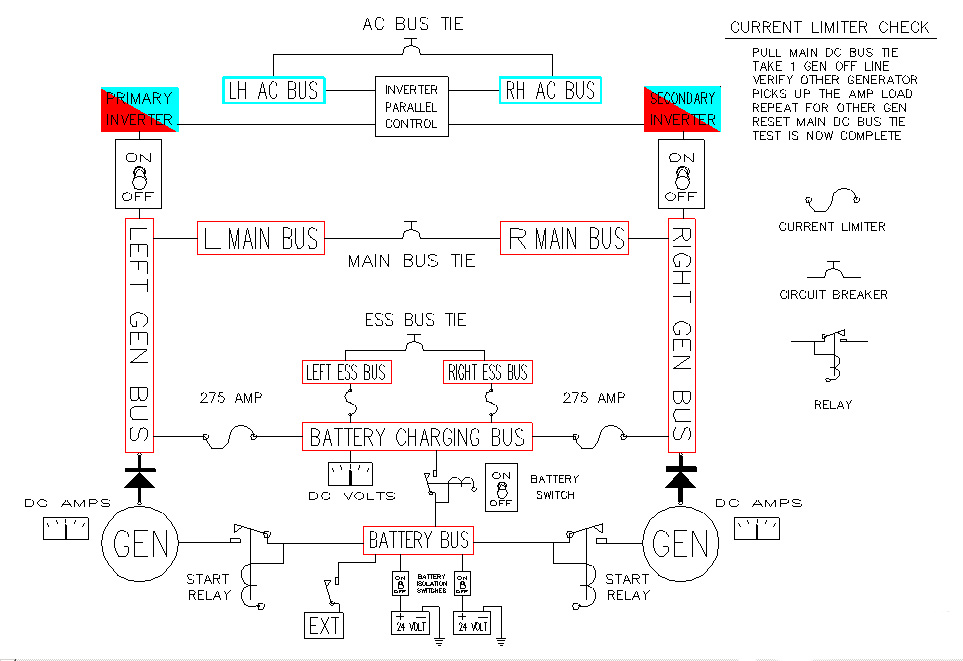

"DC" Electrical

The Lear Jet 55 DC electrical system is only slightly more complex than the earlier models. It consists of: Two batteries, usually one, but sometimes two standby batteries, two starters, two generators, several busses, some relays, current limiters, quite a few circuit breakers, and two battery switches. The main difference between the 30 series (and some later 25's) is the added "Essential" busses. They are busses that can still receive battery power with both current limiters blown.

The current limiters connect the generators to the battery

bus. The starting current goes through the start relay, and does

not pass through the current limiter. The current that recharges

the batteries does. If you blow a current limiter other than due

do an electrical short, it will probably be just after engine start when

you put the first generator online. Because the batteries are in

a discharged state, they want all of the electrons they can eat.

This is sometimes more than the current limiters can take.

|

|

|

| Voltage |

|

| Max Amps |

|

Emergency Battery

The Emergency battery switch has three positions: OFF, STANDBY, and ON. In the ON position the emergency battery powers the small third attitude indicator, it's light, and the control circuits for the landing gear and flap systems, as well as the position lights and N1 tachometers. The three green landing gear lights are also powered by the emergency battery, and will illuminate when the gear is down and locked. The red "gear door not locked" lights are not powered by this battery. In standby, it powers just the gyro and it's light. Most of these batteries will charge in the ON and Standby positions, however, some, such as the ones in the Lear 28 must be left "ON" to be charged. Some later model aircraft may be equipped with a second standby battery. This will usually power an emergency comm radio, and whatever other devices the customer would like.

If you experience loss of all main DC bus power for any reason, remember the following:

1. Emergency battery switch to ON. Landing gear extension

will be normal

except for the loss of the red gear

door warning lights.

2. Landing gear warning horn will be inop.

3. Engine stator and nacelle lip heat are on.

4. Wing and tail anti-ice, pitot static, and angle of attack

probe heat will be inop.

5. Windshield Heat will fail in the last position selected.

6. Tank to tank fuel transfer will not be possible if crossflow

valve

was closed at time of power loss.

If crossflow valve was open, the

boost pumps will fail, making

pressure fuel transfer impossible, however,

the crossflow valve will remain

open, allowing some fuel transfer due to a

very reliable power source called

gravity.

7. The AC electrical system will be inop as it receives

it's power from the DC system.

8. The hydraulic system will be inop, except for the landing

gear and flaps, as their

control circuitry is powered by

the emergency battery when the "ON" position

is selected.

9. Nosewheel steering will be inop, as it requires

both AC and DC electrical power.

10. Anti-Skid system is inop.

These things may require some thought as to how one wishes to conduct the remainder of a flight.

Normal Operation:

Battery switches ON, before engine start,

all DC busses are powered by batteries or GPU. After engine start,

all busses are powered by the generator(s), and the batteries are recharged.

Battery Overheat

Respective battery switch OFF. This prevents

battery charging. DC busses powered by generator(s). Monitor

temp of offending battery. If your Lear does not have dual battery

switches, use the battery disconnect switch for the offending battery.

All Lear 55's have dual battery switches.

"AC" Electrical System

The Lear 55 is equipped with two inverters.

Either one can supply AC power to all items on the aircraft that require

it. They normally operate in parallel, but if one fails, the other

picks up the remaining load automatically. An AC paralleling unit

aligns the phase of the two inverters to make them work in parallel.

The AC items on the Lear include: Gyros, Autopilot,

Altitude Alert, Mach trim system, Nosewheel Steering, Engine pressure gauges,

and a few other items that vary from aircraft to aircraft.

|

|

The Lear 55 is certified for flight into known or

forecast icing conditions. Starting from the front of the airplane,

The alcohol pump provides emergency anti-ice for the left windshield.

You have 2.35 gallons of alcohol to anti ice the windshield.

This system is not frequently used, as the bleed air windshield heat usually

does the job if you operate it properly.

The pitot tubes, static ports, and angle of attack

vanes are electrically heated, controlled by the "Pitot Heat" switches

in the cockpit. The windshields are heated with engine bleed air.

If you are descending into an icing environment, remember to pre heat the

windshields about 20 minutes prior to descent. This is also the case

if you are landing anyware humid. The windshield heat wil prevent

the windshield from foging up during landing. The Aux defog system

will take care of the inside, and the windshield heat takes care of the

outside. The 55 is much better than the earlier Lear Jets in this

respect. The wing leading edges are heated with engine

bleed air. The horizontal stab leading edges are heated electrically.

These systems also need to be turned on and heated up before entering icing

conditions.

Engine nacelles and stators are heated by bleed

air. The bullet shaped nose cone for the 731 engine was heated with

bleed air as well, however almost all of the airplanes have been fitted

with the conical spinners, and require no heat, as their shape and rotation

does not allow large enough amounts of ice to form to pose any hazard to

the engine. The Tt2 and Pt2 probes in the engine inlets are electrically

heated.

|

|

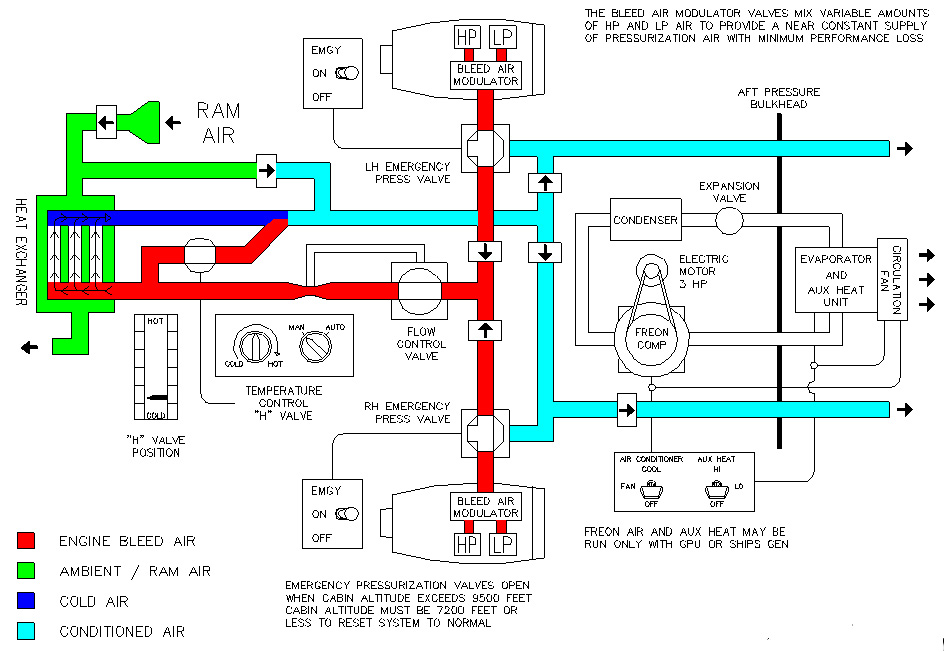

The Lear 55 is pressurized, like most airplanes,

by engine bleed air. This air comes from the HP and LP bleed sources

on the engine through a "Bleed Air Mix Valve" that regulates the bleed

air pressure by controlling the mix of LP and HP air. This air goes

through a heat exchanger in the tailcone of the airplane, and is cooled,

then goes into the cabin. Temperature is regulated by a "Damper Valve".

This valve controls the ambient airflow across the non pressurized side

of the heat exchanger. This does not provide enough cooling

for low altitude and hot weather, so a freon air conditioner is provided

for use below 18,000 feet. This freon system may not be used during

takeoff and landing, or when Stab / Wing heat is on in the Lear 55.

If it is necessary to heat the wing, you probably don't need the freon

system anyway. An Aux Heat system is installed on the Lear

55, and many earlier models. It may heat the cabin air electrically,

if you have a generator or GPU online. The cooling system switch

must be in the "Fan" position, and the Aux heat switch in high or lo.

It has various thermal protection, preventing it from burning the airplane

to the ground.

Emergency pressurization air is provided by two

emergency bleed valves that will automatically open when the cabin altitude

exceeds about 9,500 feet. These valves allow un cooled bleed air

to pressurize the cabin.

On the outflow side of things, the cabin pressure

is regulated by a main outflow valve, located at the forward end of the

pressure vessel. The automatic pressurization system requires AC

power. In the event the automatic pressurization fails, cabin pressure

may be controlled pneumatically, by the "Cherry Picker" that uses air to

move the outflow valve. Maximum differential relief at 9.7

psi, and negative pressure relief at -0.25 psi, and positive pressure

depending on the model and serial number airplane. This "Safety outflow

valve" is strictly mechanical. It requires no electrical power.

Cabin altitude limiters will close the outflow valves if the cabin altitude

reaches 11,000 ft, regardless of what else is selected.

GO

Press & Temp Control Panel Photos

|

|

|

|

|

The performance of the Lear 55 won't exactly make

your eyes water if you compare it to the earlier models. It performs

much like a 35, but is much more compfortable for the passengers and crew.

It does, however, do a bit better out of the high elevation airports because

of the wing. The pilot seats are great, quite unlike the chiropractic

torture chamber seats in the earlier Lear Jets. The table below gives

approximate performance figures. Range is figured for 6 Pax and 500

lbs of baggage. If you sharpen your pencil, you can do better than

the figures below. I used 30 minutes, 1,000 lbs fuel and 160 miles

for climb and descent, and 440 kts & 1,300 lbs per hour for high speed

cruise at FL 390. You can do better, but these are figures that will

keep you out of trouble.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The use of anti ice during takeoff will reduce

your miximum climb limited weight by 1,000 to 1,500 pounds. Runway

requirement may increase by 300 or 400 feet for Nacelle Heat only, or by

as much as 1,700 feet for Nacelle & Wing heat at the higher elevations.

If the weather is so bad that you need to use the wing heat during the

takeoff roll and initial climb to 1,500 feet AGL, you will probably have

to have the airplane de-iced as well. These are "Ball Park" figures

for general information. For a particular flight, go to the AFM and

run the charts.

Note: AFM does not mean the Flight Safety or Simuflite

checklist tabular data. As handy as those tab data charts are in

day to day operations, if you must justify why you took off at a particular

weight, the FAA and NTSB will insist you use the charts in the "Aircraft

Flight Manual" to make your case. Also, in some cases, you can

takeoff a little bit heavier with the data from the AFM, as the tabular

data usually does not address wind, runway gradient, or give you the data

for your exact pressure altitude and temperature. With tab data,

you generally go to the next higher altitude and temperature to obtain

your figures. Also, interpolation of tab data is not exact, and extrapolation

is out of the question because the relationships are not linear.

Backto: Airplane DriverHome Page